The molded air duct of the cooling tower is made of glass fiber reinforced plastics. It is formed by a composite material molding hydraulic press under the cooperation of the mold, and is molded in one time. The glass fiber reinforced plastic cooling tower air duct molding hydraulic press has a variety of structures such as three-beam four-column type and frame type. According to the specifications and sizes of the molded air duct, 1500 tons, 1800 tons, 2000 tons, 3000 tons, 4000 tons, etc. are commonly used.

The molded air duct of the cooling tower is made of FRP, and is formed by a composite material molding hydraulic press under the cooperation of the mold, using a molding process, and is molded in one time. The FRP cooling tower air duct molding hydraulic press has a variety of structures such as three-beam four-column type and frame type. According to the specifications and dimensions of the molded air duct, 1500 tons, 1800 tons, 2000 tons, 3000 tons, 4000 tons, etc. are commonly used. This article introduces a 2000-ton four-column hydraulic press molded FRP cooling tower air duct for rapid one-time molding.

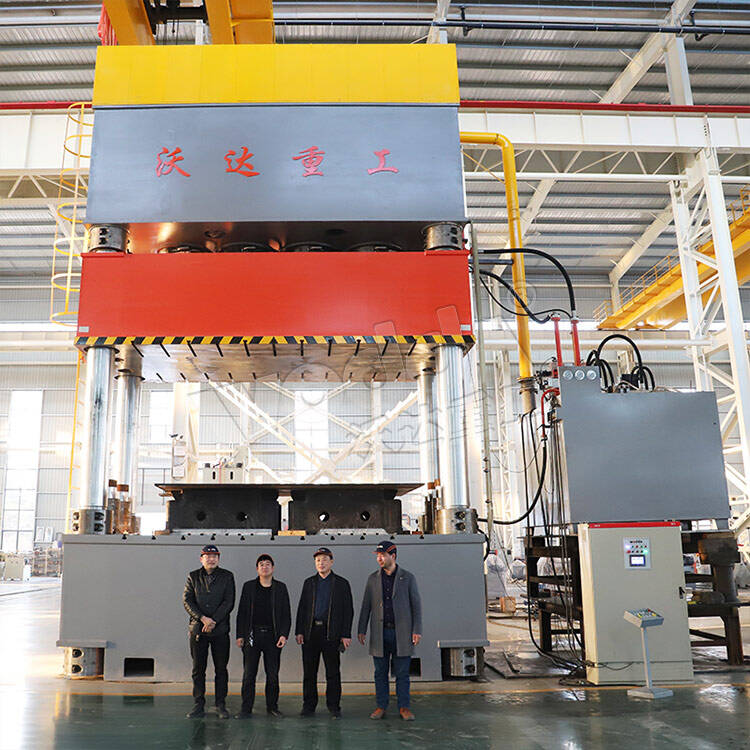

2000 tons composite material forming hydraulic press

2000 tons FRP cooling tower wind tube molding hydraulic press is FRP cooling tower production equipment, mainly composed of hydraulic press main body, hydraulic station and servo electronic control system. Servo motor oil pump group is used, in conjunction with industrial PC, pressure sensor, displacement sensor, to achieve the setting of each action of the main cylinder on the PC, the slider drive is driven by servo motor and high-speed plunger pump, so that each action of the slider can be servo-adjusted to reduce the failure rate. The slider of the molded FRP cooling tower wind tube hydraulic press has a high idle speed, which effectively prevents the pre-curing phenomenon of the molded material after entering the mold; the speed and pressure of the slider can be adjusted arbitrarily within the specified range of parameters, with a controllable pre-pressing process to increase the flow speed of the material in the mold and shorten the pressurization time; the machine has an automatic exhaust function during the pressing process, and the slider return has a micro-opening function, so that the molded product is slowly separated from the mold after forming to prevent the product from being torn and pulled; the hydraulic system is equipped with two sets of in-mold core pulling control systems, and the in-mold ejection control system is preset; multi-point ejection, blowing and other functions can be added.

Actual shot of 2000 ton FRP cooling tower air duct molding hydraulic press workshop:

2000 tons three-beam four-column hydraulic press

2000 ton four-column hydraulic press back

Customer test machine 2000 tons FRP cooling tower wind tube molding hydraulic press

2000 ton four-column hydraulic press machine inspection in workshop

Finished product of 2000 ton four-column hydraulic press molded glass fiber reinforced plastic cooling tower air duct:

FRP cooling tower fan

Features of 2000 ton FRP cooling tower air cylinder molding hydraulic press:

1. The hydraulic control adopts a cartridge valve integrated system, which has stable action, long service life, small hydraulic shock, and reduces connecting pipelines and leakage points.

2. The 2000-ton FRP cooling tower wind tube molding hydraulic press is designed through computer optimized structure, three-beam four-column structure, simple, economical and applicable.

3. Separate electrical control system, stable operation, intuitive action and easy maintenance.

4. Through the operation panel selection, two operation processes of fixed stroke and fixed pressure can be realized, and it has the functions of maintaining pressure for a long time.

5. The working pressure of the slider, the range of no-load fast descent and slow working advance can be adjusted according to work needs. The electrical control system has stable operation, intuitive action and convenient maintenance.

6. The power mechanism and electrical system are centrally arranged and controlled by buttons, which can realize two operation modes: adjustment and semi-automatic (manual injection or automatic injection).

7. The working pressure, pressing speed, high-pressure downward movement, no-load rapid downward movement and ejection stroke of the 2000-ton four-column hydraulic press can be adjusted according to the pressing process requirements of different products by pressure sensors, micro-speed regulating valves, inductive sensors, displacement sensors, etc. The molded FRP cooling tower wind duct hydraulic press can adjust the force, time and stroke parameters on the touch screen through PLC to ensure product quality and high consistency.

2000 ton four-column hydraulic press workshop test video:

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog