Brand: Shandong Woda Heavy Machinery

Model: YQ32-800T

Origin: Tengzhou, Shandong, China

Introduction: 800-ton cold extrusion hydraulic press, also known as metal cold extrusion hydraulic press, cold extrusion press, vertical three-beam four-column structure, also known as 800-ton three-beam four-column hydraulic press, uses high-pressure liquid as the power source, the maximum working pressure of the main cylinder liquid can be controlled within 25MPa, equipped with servo CNC system, with the characteristics of fast extrusion speed, high dimensional accuracy, high material utilization rate, high product strength, etc., can be installed with upper and lower push cylinders, suitable for cold extrusion product withdrawal requirements. This series of hydraulic presses are suitable for cold forging of aluminum alloys, copper, steel and other products.

This machine is an 800-ton cold extrusion forming hydraulic press, also known as metal cold extrusion hydraulic press, cold extrusion press, vertical three-beam four-column structure, also known as 800-ton three-beam four-column hydraulic press, using high-pressure liquid as the power source, the maximum working pressure of the main cylinder liquid can be controlled within 25MPa, equipped with servo CNC system, with the characteristics of fast extrusion speed, high dimensional accuracy, high material utilization rate, high product strength, etc., can be installed with upper and lower push cylinders, suitable for cold extrusion product withdrawal requirements. This series of hydraulic presses are suitable for cold forging of aluminum alloys, copper, steel and other products.

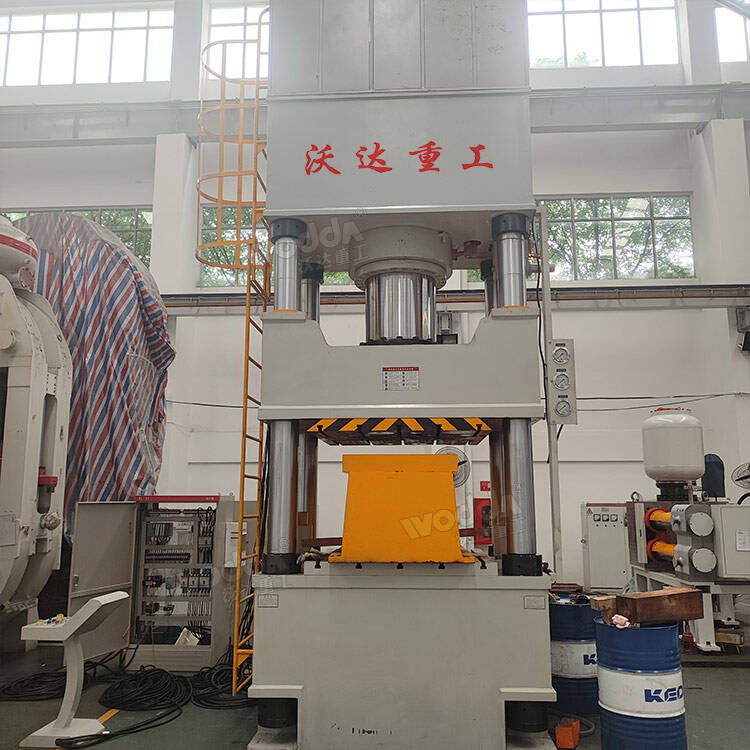

800-ton cold extrusion hydraulic press workshop

800 ton three-beam four-column hydraulic press

Application areas:

This equipment is suitable for extrusion forming of metal materials, such as forming, upsetting, drawing, expanding and bending of stepped shafts, discs and gear parts, and is particularly suitable for extrusion and forging of aluminum products. It can also realize stamping, forming, shallow drawing and shaping of metal or non-metal parts. Applicable industries include: shaping and positioning of aerospace products, auto parts, motorcycle parts, photo frames, transmission parts, tableware, signs, locks, hardware parts and tools, agricultural machinery parts and other manufacturing industries.

800 ton three-beam four-column hydraulic press technical parameters:

Equipment model: YQ32-800T

Nominal pressure: 8000KN

System pressure: 25Mpa

Slider stroke: 800mm

Opening height: 1500mm

Table size: 1500*1400mm (customized according to product specifications and mold size)

Structural form: three-beam four-column structure

Control mode: PLC+servo

Note: The above parameters are for reference only. For the actual parameters of the machine, please refer to the technical proposal of Mr. Shi from Shandong Woda Heavy Industry at 18963222388 (same number on WeChat).

The cold extrusion forming hydraulic press includes a machine body, a main oil cylinder, an electrical box and a hydraulic device; the machine body includes an upper crossbeam, a movable beam plate, a worktable and a column; the upper crossbeam, the movable beam plate and the worktable are horizontally arranged on the column, and the upper crossbeam is located above the worktable, and the movable beam plate is located between the upper crossbeam and the worktable; the main oil cylinder and the filling oil tank are arranged on the upper crossbeam, the quick cylinder and the upper beam joint oil cylinder are arranged on the main oil cylinder, and the filling pipe connects the filling oil tank and the upper beam joint oil cylinder; the upper ejection cylinder is arranged on the movable beam plate; the lower ejection rod is arranged on the worktable, and the lower ejection cylinder is connected to the lower ejection rod; the hydraulic device and the electrical box are arranged on the fixed frame; the electrical system control connects the hydraulic system. The cold extrusion forming hydraulic press has an advanced design, and has the characteristics of high precision, high speed, high efficiency, low energy consumption, low noise, stable operation, convenient operation, safety and reliability, etc. It is suitable for product forming in many industries and has practicality.

800 ton metal cold extrusion hydraulic press customer site

800-ton cold extrusion hydraulic press completed

Main structural features of cold extrusion hydraulic press:

1. It adopts three-beam four-column structure, with large tonnage, small table, compact structure and good rigidity;

2. Double speed, double motor, wide application range and high efficiency;

3. The movable workbench moves from top to bottom, which is beneficial to improve work efficiency and operation safety;

4. Optional safety photoelectric protection device greatly improves the safety protection of operators;

5. The movable workbench has high guiding precision, good rigidity and strong resistance to lateral force, which is particularly suitable for pressing products with high pressing precision and asymmetry;

6. The four columns are made of high-strength alloy steel, with hard chrome plating on the surface, and good wear resistance;

7. The oil cylinder is processed by grinding, with high finish and long service life of oil seal;

8. Use high-quality brand hydraulic valves and seals;

9. The electrical system adopts PLC control, which can realize two process actions: fixed pressure and fixed stroke.

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog