YQ32-100 ton Four column hydraulic metal stamping press machine Work pressure of the series products, pressing speed, travel range can be adjusted according to the requirements within the specified range, can achieve constant pressure and constant stroke of two kinds of Technology. When the constant pressure is formed, the pressure holding time delay and the automatic return stroke are pressed. A top out device is arranged in the middle of the working table, in addition to the top products, can be used as hydraulic cushion for the forming process of drawing parts.

The main performance characteristics:

YQ32-100 ton Four column hydraulic metal stamping press machine Work pressure of the series products, pressing speed, travel range can be adjusted according to the requirements within the specified range, can achieve constant pressure and constant stroke of two kinds of Technology. When the constant pressure is formed, the pressure holding time delay and the automatic return stroke are pressed. A top out device is arranged in the middle of the working table, in addition to the top products, can be used as hydraulic cushion for the forming process of drawing parts.

Application:

YQ32-100 ton Four column hydraulic metal stamping press machine For Stretching, such as stamping, bending, flanging sheet stretching, and can be engaged in correction, press fit, plastic products, powder products, compression molding.

| Specification | Unit | 100T | |

| Nominal force | KN | 1000 | |

| Ejecting force | KN | 20 | |

| Max. pressure of liquid | MPa | 25 | |

| Stroke of slider | mm | 500 | |

| Max. opening height | mm | 800 | |

| Working table size | mm*mm | 700x620 | |

| Ejecting stroke | mm | 200 | |

| Speed of slider | Descend speed | mm/s | 80 |

| Working speed | mm/s | 16-24 | |

| Return speed | mm/s | 100 | |

| Motor power | KW | 7.5 | |

| Weight | T | 2.4 | |

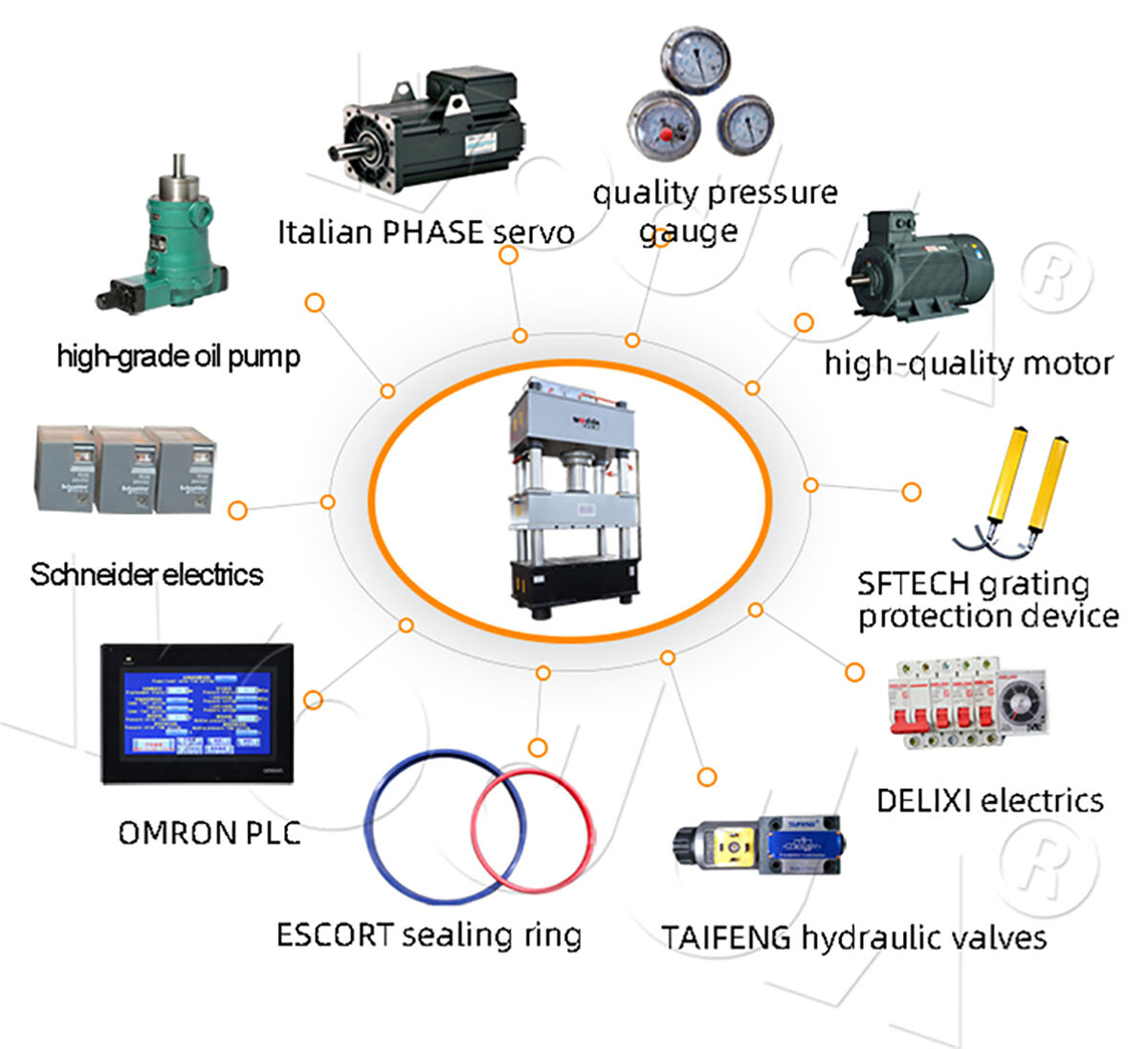

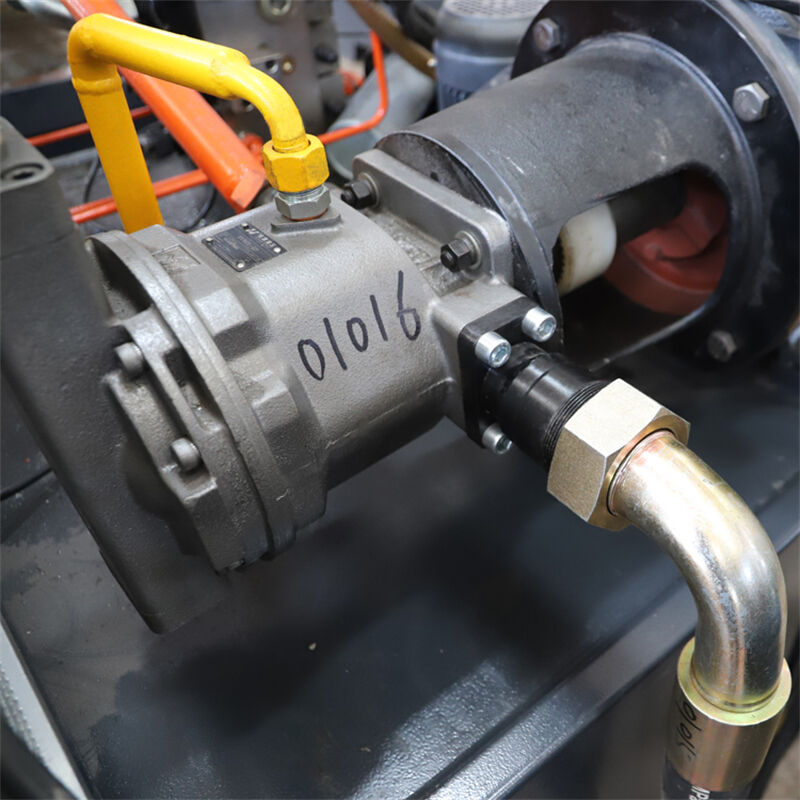

Compared with the plug-in oil pump, the horizontal positioning of the oil pump can reduce the heat generation, the oil temperature rises slowly, and the machine life is extended.

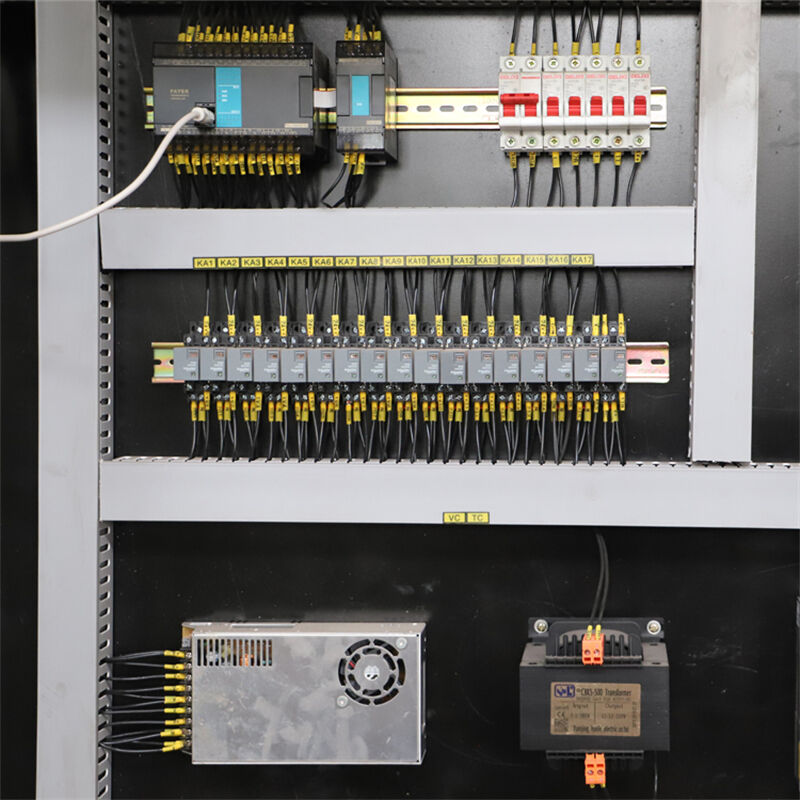

Good quality China electrics.PLC Controller can be choosed.

Hydraulic actuators have stable transmission and strong anti-interference ability, especially good performance at low speed. Need extra cost.

Red copper gaskets are used at the joints to prevent oil leakage for a long time.

Separate hydraulic and electrical control system.Centralized control with buttons.Both fixed and constant pressure forming processes can be realized With pressure display Stroke, pressure adjustment and other functions.

YQ32-100 ton Four column hydraulic metal stamping press machine

1.The four column metal stamping press machine surface with anti-rust treatment,

2.The four column metal stamping press machine inner layer of plastic waterproof packaging,

3.The four column metal stamping press machine outer layer of thick wood or steel frame fixed,And then use a synthetic board package.

Combined container transport, or separate container transport.

Q:How about your machine quality?We are worry about the quality.

A:Woda is a mature brand in China. through our several years research in technology , our design including strcture and detailed sercurity and precision has enhanced greatly, and can match all the CE standard or mor strict standard.Our machines distribute worldwide to about 20 countries where there are metal plate industry.And where there are our machines, there are good reputation and terminal user satisfaction.

Q:Why Choose your company?

A:We can provide customized services according to customer requirements. We also have professional R &D team and fast response sales team. Strictly control each step of QA &QC system processes. We have an after sale service team than can quickly solve any problem you may have in the use.

Q:How to select your machine?

A: you can tell me your specifications ,we can choose the best model for you . we also have some regular model for you to choose.You can also provide the drawings, size , photos of the products, we can design the suitable machine for you according to your requirements. After the machine is finished, you can also provide samples and we will test it for you.

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog