The 400-ton silicon carbide powder briquetting machine adopts a four-beam four-column structure to ensure stability and high precision, and is suitable for various high-precision press fitting and molding. It adopts mechanical, electrical, hydraulic and gas integrated control, with automatic feeding device, floating pressurization, so that the product molding density can be effectively controlled. The combined superimposed valve block used in the hydraulic system ensures continuous and frequent stable operation of the hydraulic press; the mechanical block positioning and stepless adjustment mechanism of the three positions of loading, molding and demoulding determine the stability and adjustability of the geometric dimensions of the product. Equipped with an oil cooling device. It adopts PLC and human-machine interface centralized control, and is equipped with a mechanical limit device to ensure the consistency of the product.

As an inorganic non-metallic material, silicon carbide has the characteristics of high temperature resistance and wear resistance, and is a kind of refractory material. Silicon carbide briquette is a powder body configured with silicon carbide micropowder as the main raw material. It is pressed and formed by a hydraulic press and has good wear resistance, thermal shock resistance, and corrosion resistance. According to the design and manufacturing experience of Shandong Woda Heavy Industry, the silicon carbide micropowder pressing and forming adopts a 400-ton four-beam four-column hydraulic press, and one mold produces four pieces. This machine is also called silicon carbide powder briquetting machine, which is an ideal processing equipment for the production of pressed silicon carbide micropowder.

Silicon carbide powder compact

The 400-ton four-beam four-column hydraulic press consists of four columns and four crossbeams. It is a commonly used powder molding hydraulic press equipment that can provide higher pressure to meet the requirements of the powder product process for pressing force. It can ensure that the powder material reaches the required density and strength during the pressing process. It has high operating stability and can maintain consistent pressure and shape control. By adjusting the hydraulic valve, precise control of parameters such as pressure and speed can be achieved. This machine is suitable for the pressing and molding of ceramic powders, powders, powder metallurgy, graphite powders, refractory materials, non-powder products, etc.

The working pressure, forming speed and stroke of the 400-ton four-beam four-column hydraulic press can be adjusted according to the process requirements. The machine has an independent power mechanism and electrical system, and adopts button centralized control. It can realize three operation modes: manual, semi-automatic and automatic, and can realize two modes: constant pressure and fixed stroke.

400 tons silicon carbide powder briquetting machine customer on-site demonstration:

400 tons silicon carbide powder briquetting machine customer site

400-ton four-beam four-column hydraulic press commissioning in customer workshop

Automatic powder feeding device

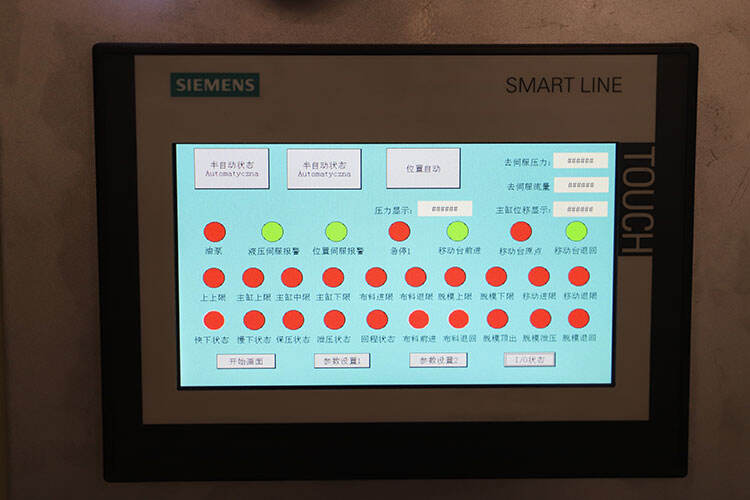

PLC numerical control display

The 400-ton silicon carbide powder briquetting machine adopts a four-beam four-column structure to ensure stability and high precision, and is suitable for various high-precision press fitting and molding. It adopts mechanical, electrical, hydraulic and gas integrated control, with automatic feeding device, floating pressurization, so that the product molding density can be effectively controlled. The combined superimposed valve block used in the hydraulic system ensures continuous and frequent stable operation of the hydraulic press; the mechanical block positioning and stepless adjustment mechanism of the three positions of loading, molding and demoulding determine the stability and adjustability of the geometric dimensions of the product. Equipped with an oil cooling device. It adopts PLC and human-machine interface centralized control, and is equipped with a mechanical limit device to ensure the consistency of the product.

Some parameters of the 400-ton four-beam four-column hydraulic press:

Equipment model: Four-beam four-column hydraulic press

Nominal pressure: 4000KN

System pressure: 25Mpa

Slider stroke: 400mm

Opening height: 1020mm

Table size: 1000*600mm

Control mode: PLC+servo

Slider speed: Customized

Note: The above parameters are for reference only.

400 tons silicon carbide powder briquetting machine advantages:

1. High stability and precision;

2. Centrally support all formwork at the extrusion position;

3. Short setup time and quick die change;

4. Programming design, modify the action program according to requirements;

5. Low consumption and energy-saving design;

6. The 400-ton silicon carbide powder briquetting machine has an independent servo system and electrical system, and has floating pressing, which effectively controls the product molding. Two demoulding methods, protective demoulding and general demoulding, are available. The electrical control adopts PLC programmable controller;

7. It adopts centralized button control and is equipped with a mechanical limit device to ensure the consistency of the products, with the characteristics of stability, accuracy and high efficiency;

8. The filling is more uniform and the finished product is pushed out more smoothly;

9. 400-ton four-beam four-column hydraulic press has automatic pressure monitoring and high safety performance;

10. Carry out powder transfer and hydraulic proportional floating molding;

11. The servo drive has fast molding speed and low mold wear;

12. Simple structure and easy operation.

The structure of 400-ton four-beam four-column hydraulic press:

1. The main body of the 400-ton four-beam four-column hydraulic press consists of an upper crossbeam, a slide block, a workbench, a column, a locking nut and an adjusting nut.

2. Main cylinder: The oil cylinder structure of this machine is a piston type oil cylinder, which consists of a cylinder body, a guide sleeve, a piston head, a piston rod, a lock nut, a connecting flange, a cylinder port flange, etc.

3. The travel limit device is located on the right side of the main machine body and consists of a bracket, a bumper and a travel switch.

4. The hydraulic system consists of energy conversion devices (pumps and cylinders), energy regulation devices (various valves) and energy transmission devices (oil tanks, pipelines).

5. Electrical control system

6. Lubrication system

7. Safety protection system

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog