Shandong Woda Heavy Industry has designed a 1,000-ton plastic building formwork forming hydraulic press, which adopts a three-beam, four-column multi-cylinder structure design and is dedicated to molded building formwork. The equipment is equipped with PLC and servo hydraulic system, which can be operated with one button. It has the characteristics of energy saving, high efficiency, low noise, low heat generation, and high control accuracy. The equipment is economical in cost and can produce different products by changing the mold.

Plastic building formwork is a new type of building formwork, replacing traditional steel formwork, aluminum formwork, wooden formwork, square timber, etc. It has the advantages of energy saving and environmental protection, simple production process, and recyclability. Shandong Woda Heavy Industry has designed a 1,000-ton plastic building formwork forming hydraulic press, which adopts a three-beam four-column multi-cylinder structure design and is dedicated to molded building formwork. The equipment is equipped with PLC and servo hydraulic system, which can be operated with one button. It has the characteristics of energy saving, high efficiency, low noise, low heat generation, and high control accuracy. The equipment is economical and can produce different products by replacing molds.

Plastic building formwork

1000 ton plastic building formwork forming hydraulic press

The 1000-ton plastic building formwork forming hydraulic press has the advantages of fast closing, high efficiency and energy saving. Equipped with an in-mold core pulling control system and a preset in-mold ejection control system, it can realize a series of actions such as fast descending, segmentation and pressing, segmented deflation, working, pressure holding, slow mold opening, fast return, slow demolding, fast ejection, ejection stop, fast return, etc., and the temperature can be controlled at multiple points. The plastic building formwork forming hydraulic press designed and manufactured by Shandong Woda Heavy Industry adopts a four-column guide structure with high guiding accuracy and strong resistance to eccentric loads. It is suitable for products with high pressing accuracy requirements; the fuselage is made of forged steel with fine processing and thickening treatment, and has good rigidity and strong resistance to deformation; it is equipped with a PLC servo system and has the advantages of rapid prototyping, energy saving, and environmental protection. To purchase and customize high-quality plastic building formwork forming hydraulic presses, you can choose our Shandong Woda Heavy Industry, with short delivery time, good quality of machinery and equipment, and low failure rate.

1000 ton plastic building formwork forming hydraulic press technical parameters: (for reference only)

| Model/technical parameters | 1000T | 800T | |

| Nominal force KN | 10000 | 8000 | |

| System pressure MPa | 25 | 25 | |

| Return force KN | 1000 | 800 | |

| Slide stroke mm | 1200 | 1200 | |

| Maximum opening height mm | 1500 | 1500 | |

| Table effective size mm | Around | 2200 | 2200 |

| Front and rear | 1200 | 1200 | |

| Low speed mm/s | 300 | 300 | |

| Pressing speed mm/s | 45060 | 45095 | |

| Slow return speed mm/s | 6 | 6 | |

| Fast return speed mm/s | 125 | 180 | |

| Motor power kw | 45 | 45 | |

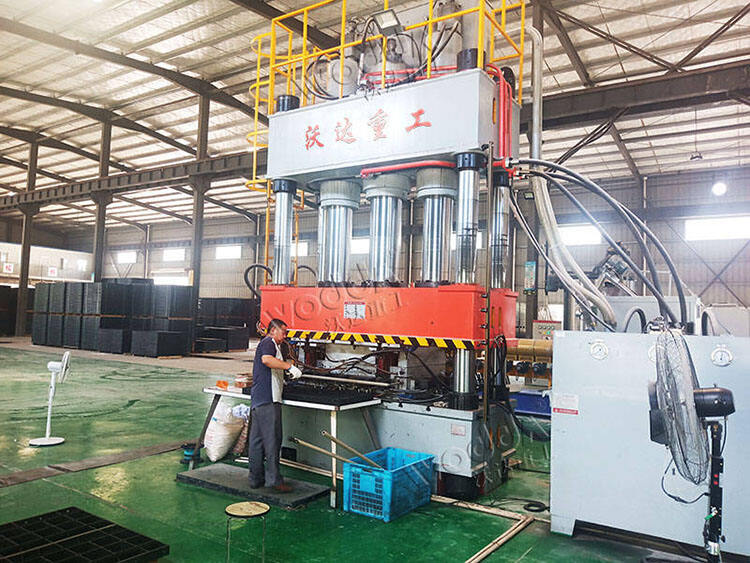

1000 ton plastic building formwork forming hydraulic press workshop and customer site photos:

1000 ton four-column hydraulic press

1000 tons of plastic building formwork forming hydraulic press customer processing site

1000 ton four-column hydraulic press for molded plastic building formwork

Plastic building formwork forming hydraulic press

Finished plastic building formwork

1000 ton four-column hydraulic press molding building plastic formwork molding process flow:

(1) Adding materials: Add a specified amount of material into the mold as needed. The amount of material added directly affects the density and size of the product.

(2) Mold closing: After adding materials, the male and female molds are closed. When closing the molds, use fast speed first, and then change to slow speed when the male and female molds are in contact.

(3) Exhaust: When thermosetting plastics are molded, moisture and low molecular weight substances are often released. In order to remove these low molecular weight substances, volatile substances and air in the mold, after the plastic reaction in the mold cavity of the plastic mold has been carried out for an appropriate time, the pressure can be released and the mold can be loosened to vent for a very short time.

(4) Curing: The curing of thermosetting plastics is to maintain the molding temperature for a period of time so that the condensation reaction of the resin reaches the required degree of cross-linking, so that the product has the required physical and mechanical properties.

(5) Demolding: Demolding is usually done by ejecting the rod. Products with molding rods or certain inserts should first be demolded with special tools to remove the molding rods, etc., and then demolded.

According to the material, thickness and size of the building formwork, Shandong Woda Heavy Industry can customize 800 tons, 1000 tons, 1500 tons, 2000 tons, 3000 tons, 4000 tons and other tonnages of plastic building formwork forming hydraulic presses for customers. The machine body is composed of an integral machine body, main cylinder, stroke, limit device, etc., which are interconnected by pipelines and electrical systems. The working pressure, pressing speed and stroke range can be specially customized according to process requirements.

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog