Brand: Shandong Woda Heavy Machinery

Model: YQ32 series

Origin: Tengzhou, Shandong, China

Introduction: Molded plastic building formwork hydraulic press is an ideal processing equipment for manufacturing plastic formwork. It adopts a three-beam four-column multi-cylinder structure design and is specially used for molded building formwork. The equipment is equipped with PLC and servo hydraulic system, which can be operated with one button. It has the characteristics of energy saving, high efficiency, low noise, low heat generation, and high control accuracy. The equipment is economical in cost and can produce different products by changing the mold.

Building formwork is an important tool for concrete structure construction. China's real estate market is hot, and the demand for construction resources is huge. The amount of building formwork is huge. Traditional steel formwork and bamboo formwork are subject to high costs and forest resource protection. New composite building formwork has emerged. The new composite building

formwork has the characteristics of low cost, fireproof, waterproof, high temperature resistance, acid and alkali resistance, environmental protection, bending resistance, impact resistance, reusability, quick disassembly and assembly, convenient transportation, good molding effect, easy maintenance, etc., and has been widely used in construction.

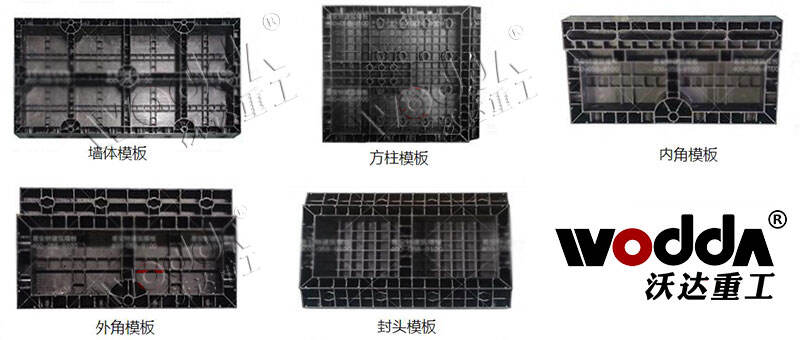

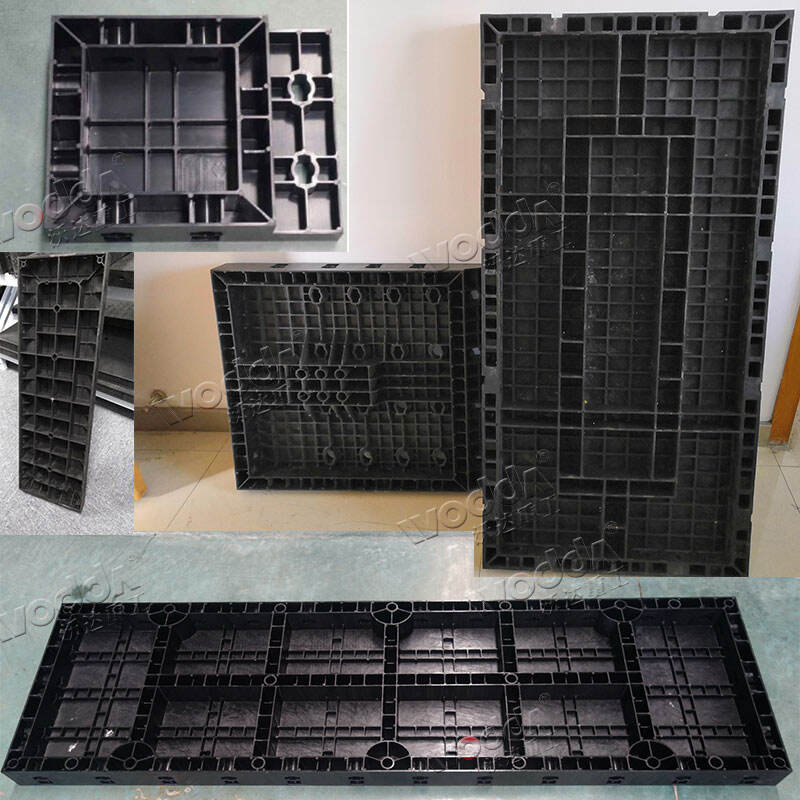

The raw materials of long fiber reinforced thermoplastic (LFT-D) composite building formwork mainly include matrix resin (polypropylene/nylon/polyester/heat-resistant styrene, etc.), reinforcing fiber (glass fiber/carbon fiber), and modified additives need to be added, such as solubilizers, masterbatches, antioxidants/ultraviolet additives, etc. The thickness of the contact surface with concrete is 5mm, and the back reinforcement is 10-20mm. The molding process of long fiber reinforced thermoplastic (LFT-D) composite building formwork mainly uses a twin-screw extruder to quantitatively cut, preheat and evenly disperse the glass fiber and thermoplastic molten polymer through the twin-screw extruder die head to extrude strip plastic, which is then conveyed by heat preservation and sent to a 1000-ton composite plastic building formwork hydraulic press by an automatic loading robot for molding, and then the finished product is clamped out of the press by a finished product unloading robot. As shown in the following figure:

Shandong Woda Heavy Tools has rich experience in the production and service of long fiber reinforced thermoplastic (LFT-D) composite material building formwork hot pressing forming hydraulic presses. The 1000-ton composite plastic building formwork hydraulic press is well-known in the industry. It can also configure 800-ton, 1250-ton, 1500-ton, and 2000-ton long fiber reinforced thermoplastic (LFT-D) composite material building formwork hot pressing forming hydraulic presses according to the size of the customer's composite building formwork.

| Model/Technical Parameters | 1000T(three cylinders) | 800T (three cylinders) | 2000T (three cylinders) | |

| Nominal force KN | 10000 | 8000 | 20000 | |

| System pressure MPa | 25 | 25 | 25 | |

| Return force KN | 1000 | 800 | 1500 | |

| Slider stroke mm | 1200 | 1200 | 1200 | |

| Maximum opening height mm | 1500 | 1500 | 1500 | |

| Effective size of workbench (mm*mm) | Left and right (size between four columns) | 2200 | 2200 | 3800 |

| Front to back (front to back of workbench) | 1200 | 1200 | 1600 | |

| Idle downward speed mm/s | 350 | 350 | 350 | |

| Pressing speed mm/s | 5-14 | 6-18 | 8-15 | |

| Slow return speed mm/s | 6 | 6 | 6 | |

| Fast return speed mm/s | 160 | 180 | 150 | |

| Motor power kw | 45 | 45 | 75 | |

The hydraulic press for hot pressing of long fiber reinforced thermoplastic (LFT-D) composite building formwork must be equipped with a servo system, oil temperature cooling device, core pulling system, micro mold opening system, etc. It can also be equipped with a manipulator or a movable workbench as needed.

The following are pictures of finished products taken at several Woda customers' composite building formwork production sites. If you need more detailed parameters and quotations, please call us for consultation.

Woda Heavy Industry, a high-tech enterprise, a hydraulic press manufacturer, ISO9001 quality management system and EU CE certification enterprise, has won many national patents.

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog