Brand: Shandong Woda Heavy Machinery

Model: YQ32 series

Origin: Tengzhou, Shandong, China

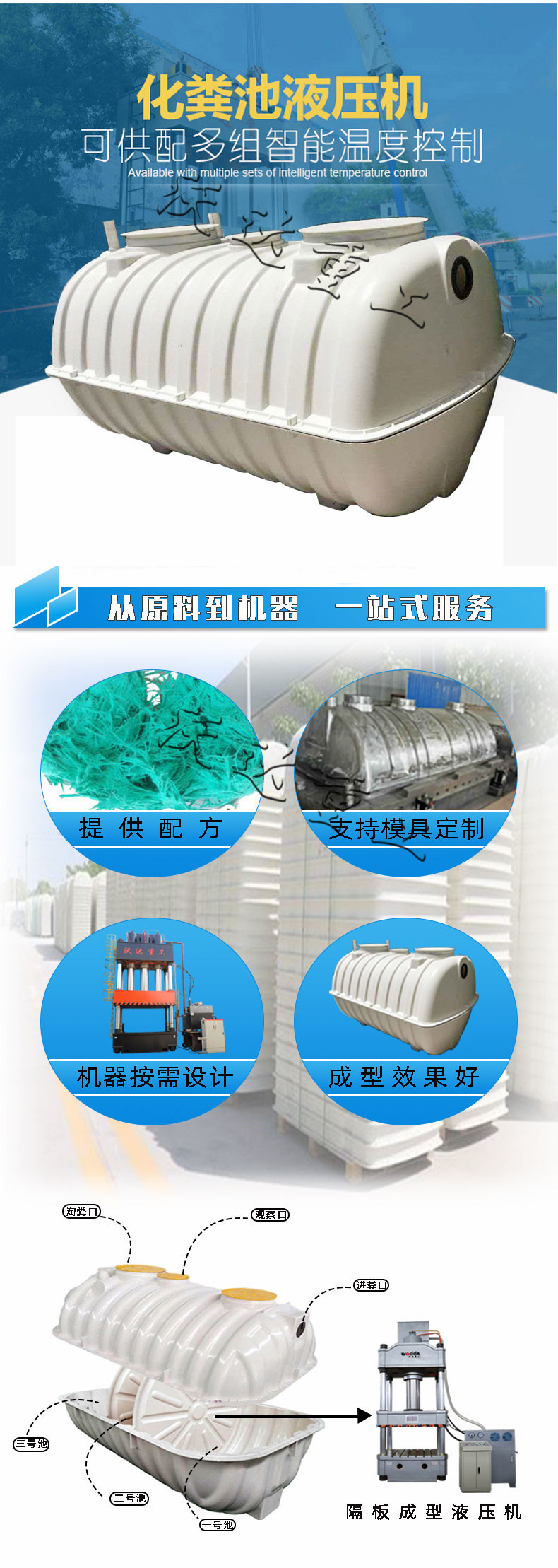

Introduction: The 1200-ton FRP septic tank forming hydraulic press adopts a three-beam four-column structure, which is suitable for pressing 1 cubic meter and 1.2 cubic meter light FRP septic tanks. The FRP septic tank forming hydraulic press adopts servo drive, which can realize semi-automatic production, high efficiency, safety and reliability!

FRP septic tanks are usually molded by four-column hydraulic presses. Customized models include 1500-ton, 2000-ton, and 2500-ton hydraulic presses, which are used to press one cubic meter, one and a half cubic meters, and two cubic meters of FRP septic tanks. The FRP septic tank hydraulic press selected mainly depends on the size of the FRP septic tank.

The molded FRP septic tank only needs to place the SMC sheet in the mold cavity, and then control the hydraulic press to automatically complete the action process of pressing down-maintaining pressure-opening the mold-returning, and the production can be completed in one time. The FRP septic tank hydraulic press has high molding efficiency and can achieve one-time molding.

The advantages of 1200 tons FRP septic tank forming hydraulic press are:

1. FRP molded septic tank is an emerging product for rural toilet renovation in new rural construction. Compared with traditional cement septic tanks, it has many advantages. Therefore, the production and manufacturing industry of molded FRP septic tanks is developing in full swing.

2. FRP septic tank hydraulic press is a commonly used machine for producing FRP molded septic tanks. Common septic tank hydraulic press oil models include 1000 tons, 1200 tons, 1500 tons, and 2000 tons.

3. In order to meet the efficiency requirements of modern industrial production, the FRP septic tank hydraulic presses produced by Shandong Woda Heavy Industry are equipped with a PLC servo control system to achieve semi-automatic production.

The commonly used sizes of FRP septic tanks are 1.5 cubic meters, 2 cubic meters, and 2.5 cubic meters. A 1.5 cubic meter septic tank requires a 1500 or 1800 ton hydraulic press, a 2 cubic meter requires a 2000 ton hydraulic press, and a 2.5 cubic meter requires a 2500 ton hydraulic press. The production process of FRP septic tanks is to first cut the massed linear raw materials through a sheet machine, stir them into a paste, press them into sheets, and then divide them into pieces and put them on a hydraulic press for pressing. The mold is heated, and a mold temperature controller is required to heat the mold. Pressure maintenance is required during production.

The production efficiency of molded septic tanks is 120 to 160 in 24 hours a day, one piece can be produced every 4 minutes, and a set can be produced every 8 minutes. It can be said that the efficiency is very high.

1200 ton FRP septic tank forming hydraulic press technical parameter table

| Tonnage | 1000T | 1000T | 1200T | 1200T | 1200T | 1500T | 1500T | 1500T | 1500T | 2000T | 2000T |

| Liquid pressure MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective travel of the slider mm | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Maximum opening height mm | 2600 | 2600 | 2600 | 2600 | 2600 | 2600 | 2600 | 2600 | 2600 | 2600 | 2600 |

| Table size mm | 3000x2000 | 3500x2400 | 3200x2200 | 3500x2400 | 3800x2800 | 3000x2000 | 3500x2000 | 3800x2400 | 3500x2400 | 3200x2500 | 3800x2500 |

| Maximum opening force KN | 1000x2 | 1000x2 | 1600x2 | 3200 | 3200 | 3200 | 3200 | 3200 | 3200 | 5000 | 5000 |

| Jacking force T | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 |

| Airborne descent speed mm/s | 120-150 | 120-150 | 120-150 | 120-150 | 120-150 | 150 | 150 | 150 | 150 | 150-200 | 150-200 |

| Working speed mm/s | 10-18 | 6-12 | 5-15 | 5-15 | 5-15 | 6-13 | 6-13 | 6-13 | 6-12 | 6-15 | 6-15 |

| Return speed mm/s | 120 | 100 | 80-120 | 80-120 | 80-120 | 115 | 115 | 115 | 100 | 150 | 150 |

| Motor power KW | Servo | Servo | Servo | Servo | Servo | Servo | Servo | Servo | Servo | Servo | Servo |

Function: The 1200-ton FRP septic tank molding hydraulic press is suitable for the pressing process of various plastic materials, such as stamping, bending, flanging, etc. It can also be engaged in correction, press fitting, grinding wheel molding, plastic products, rubber products and powder products. The working pressure, pressing speed and stroke range of the 1200-ton FRP septic tank molding hydraulic press can be adjusted within the specified range according to the process requirements. It can realize both constant pressure and fixed stroke process. The workbench is equipped with an ejection device. In addition to ejecting the product, it can be used as a hydraulic pad for the molding process of stretching the part.

Shandong Woda Heavy Machinery is a company focusing on the research and development, production and service of large and medium-sized forging machine tools. It has an annual output value of nearly 200 million yuan and a plant area of more than 30,000 square meters. Its main products include three-beam four-column hydraulic presses , four-beam four-column hydraulic presses, single-column hydraulic presses, gantry hydraulic presses, frame hydraulic presses, powder forming hydraulic presses, metal stretching hydraulic presses, fiberglass molding hydraulic presses, composite material molding hydraulic presses, forging hydraulic presses, punching machines, press-fitting straightening machines and various supporting molds (punching, stretching, molding, forging), etc. Its customers cover more than 300 cities across the country and overseas regions such as Central Asia, Europe, Africa, and South America.

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog