The 315-ton four-column hydraulic press has a work surface of 800x800mm and a slide stroke of 500mm. It is independently developed, produced and designed by the company. The equipment consists of two major parts: the main machine and the control mechanism, which are connected to form a whole through pipelines and electrical devices. The main machine includes the machine body, main cylinder, ejector cylinder, stroke limiter, etc. The control mechanism includes a hydraulic pump station (power system), an electrical box, etc.

This machine is a 315-ton four-column hydraulic press with a work surface of 800x800mm and a slide stroke of 500mm. It is independently developed, produced and designed by the company. The equipment consists of two major parts: the main machine and the control mechanism, which are connected to form a whole through pipelines and electrical devices. The main machine part includes the machine body, main cylinder, ejector cylinder, stroke limiter, etc. The control mechanism includes a hydraulic pump station (power system), an electrical box, etc.

315 ton four-column hydraulic press

This series of four-column hydraulic presses are universal pressing equipment, suitable for the pressing process of plastic materials. Such as powder product molding, plastic product molding, cold (hot) extrusion metal molding, thin plate extension, and stamping, bending, flanging, correction and other processes. The working pressure, pressing speed and slider stroke of the 315-ton four-column hydraulic press equipment can be adjusted according to customer needs and production process needs, and can complete three process modes: ejection process, non-ejection process, and stretching process. Each process can also be divided into two options: fixed pressure and fixed stroke. The fixed pressure molding process has pressure holding, delay, and automatic return after pressing. In addition to the above functions, this series of four-column hydraulic presses also has ejection, delay, and automatic return in the ejection cylinder.

315 ton four-column hydraulic press technical parameters:

| Item | Unit | 315t-F | 315t-A | 315t-A-Z | 315t-B | 315t- National standard |

| Nominal Pressure | KN | 3150 | 3150 | 3150 | 3150 | 3150 |

| Maximum Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 |

| Slide Travel | mm | 400 | 500 | 500 | 600 | 800 |

| Maximum Opening Height | mm | 700 | 900 | 900 | 1000 | 1250 |

| Table Size | mm | 700X700 | 800X800 | 800X800 | 1000X1000 | 1260X1200 |

| Down Speed In The Air | mm/s | 60 | 80 | 160 | 100 | 100 |

| Working Speed | mm/s | 6-12 | 6-12 | 6-12 | 6-12 | 6-15 |

| Return Speed | mm/s | 60 | 60 | 85 | 60 | 80 |

| Motor Power | KW | 11 | 15 | 15 | 15 | 22 |

| Oil Pump Displacement | ml/r | 63 | 63 | 63 | 63 | 80 |

| Ejecting Force | t | 50 | 63 | 63 | 63 | 63 |

| Ejection Stroke | mm | 250 | 250 | 250 | 250 | 250 |

Features of 315 ton four-column hydraulic press:

1. It adopts a four-column structure with good rigidity, high precision, compact structure and easy production and processing;

2. The hydraulic control adopts a cartridge valve integrated system, which reduces leakage points, has small impact, reliable action, and ensures the service life of the hydraulic press;

3. Hydraulic cylinder sealing components have strong processing reliability and long service life;

4. The 315-ton four-column hydraulic press has an automatic guide rail lubrication device to fully protect the guide column and maintain accuracy;

5. Realize mechatronic safety devices, such as the support circuit of the lower chamber of the oil cylinder, the interlocking circuit of the upper and lower chambers of the oil cylinder, etc., which have good safety;

6. The electrical system adopts CNC PLC control, which can realize one-key operation, and the processing of workpieces is simple and easy to operate;

7. The 315-ton four-column hydraulic press can realize two molding processes: fixed pressure and fixed stroke, and has the function of pressure holding and time delay;

8. According to different processing techniques, the working pressure and working stroke can be adjusted within a certain range, which is simple and easy to operate;

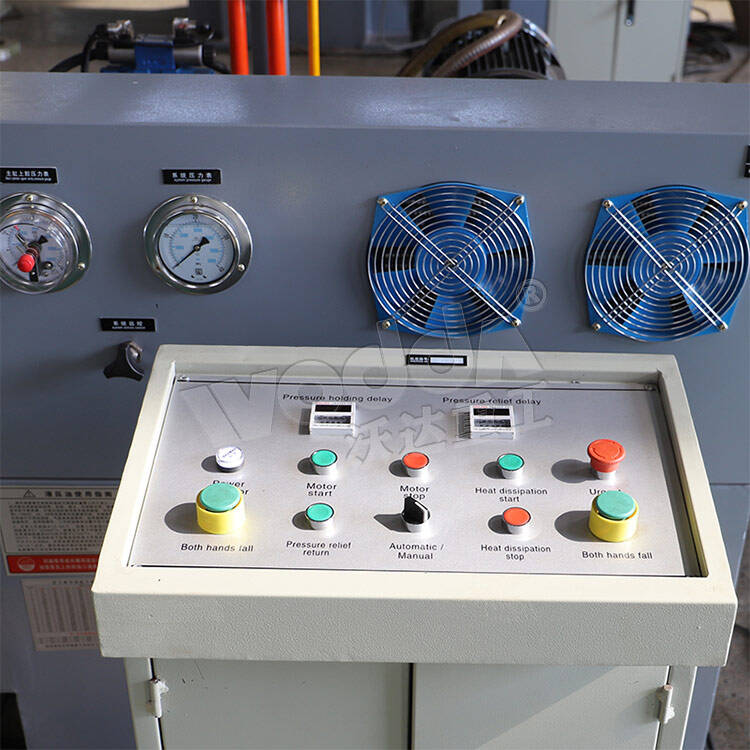

Actual photos of the 315-ton four-column hydraulic press workshop:

315 ton four-column hydraulic press workshop test video:

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog