Hot die forging hydraulic press is a high-precision forging equipment with forging technology. It has two structures: four-column type and frame type. It has high production efficiency, simple operation, convenient maintenance, and is suitable for automated forging production lines. Commonly used are 400 tons, 500 tons, 630 tons, 800 tons, 1000 tons, 1500 tons, 2000 tons, 3000 tons, etc.

500-ton servo hot die forging hydraulic press is also called 500-ton four-column hydraulic press. This equipment is suitable for hot die forging and isothermal superplastic forming of difficult-to-deform materials such as aluminum alloy, titanium alloy, high-temperature alloy, powder alloy, etc. Its forgings have high precision, high material utilization, high productivity, easy automation, low requirements for workers' operating skills, low noise and vibration, etc. Therefore, it is increasingly widely used in modern forging production and is an indispensable high-precision forging equipment for modern forging production. This machine adopts PLC servo and touch screen control, and the process action can realize multiple operation modes such as inching, semi-automatic and automatic. The working pressure and travel range of this machine can be adjusted according to the process needs.

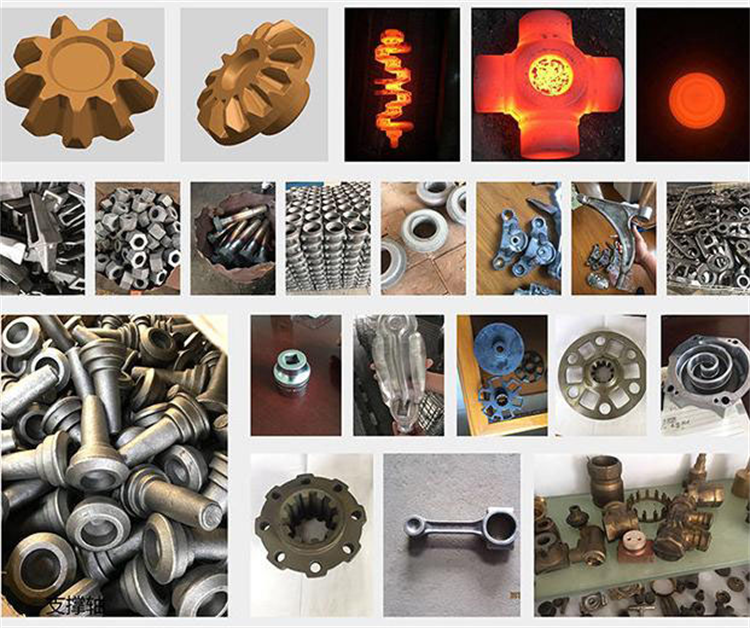

Hot die forging products

500-ton servo hot die forging hydraulic press_500-ton four-column hydraulic press workshop physical picture:

Hot die forging press

500 ton hot die forging hydraulic press

500 ton four-column hydraulic press

Lower cylinder

PLC digital display

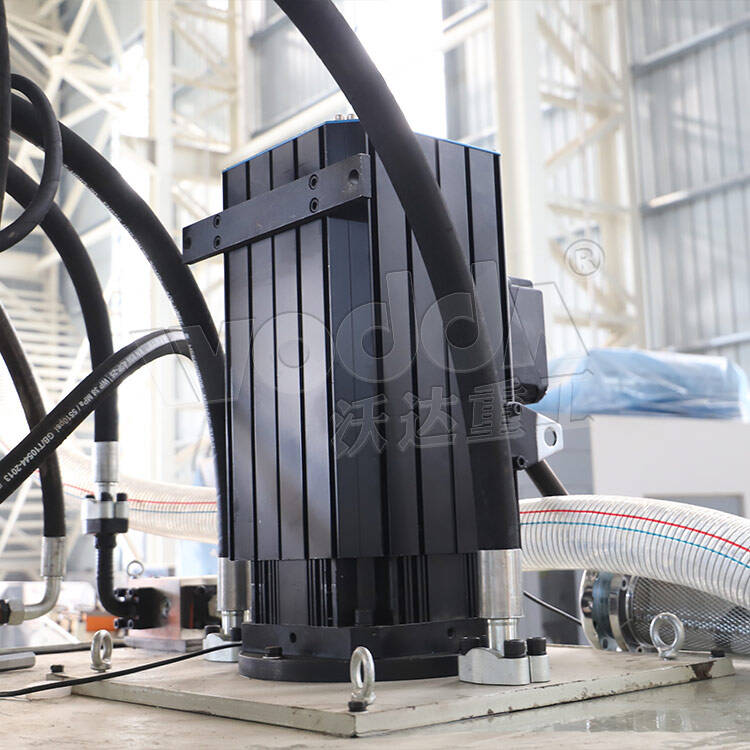

Servo Motor

500 ton servo hot die forging hydraulic press_500 ton four-column hydraulic press parameters:

Machine model: YQ32-500T

System pressure: 25Mpa

Nominal pressure: 5000KN

Slider stroke: 700mm

Table size: 800x800mm

Opening height: 1000mm

500 ton servo hot die forging hydraulic press_500 ton four-column hydraulic press features and advantages:

1. The dynamic capacity of this machine is increased and the production efficiency is improved.

2. The stroke is fast, the contact time between the forging material and the die is shortened, and the service life of the die is increased.

3. There are working windows on both sides of the frame, which are convenient for conveying forging materials and can complete fully automatic stamping operations.

4. High production efficiency, simple operation, easy maintenance, and reduced production costs.

5. Servo numerical control system reduces noise pollution and meets environmental protection requirements.

6. Reduce noise pollution and comply with environmental protection laws.

7. After computer optimization design, the four-column structure is simple, economical, practical, with high forging precision and reduced processing allowance. It is suitable for warm forging operations and can also be used for cold forging.

8. The hydraulic system has automatic protection devices such as multi-level overload protection, oil temperature alarm, oil level alarm protection, etc. The electrical system adopts mature PLC control to ensure the safety of equipment and operators.

Hot die forging hydraulic press is a high-precision forging equipment with forging technology. It has two structures, four-column and frame, and is suitable for automated forging lines. It has high production efficiency, simple operation, convenient maintenance, and is suitable for automated forging lines. Commonly used are 400 tons, 500 tons, 630 tons, 800 tons, 1000 tons, 1500 tons, 2000 tons, 3000 tons, etc.

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog