Brand: Shandong Woda Heavy Machinery

Model: YQ32 series

Origin: Tengzhou, Shandong, China

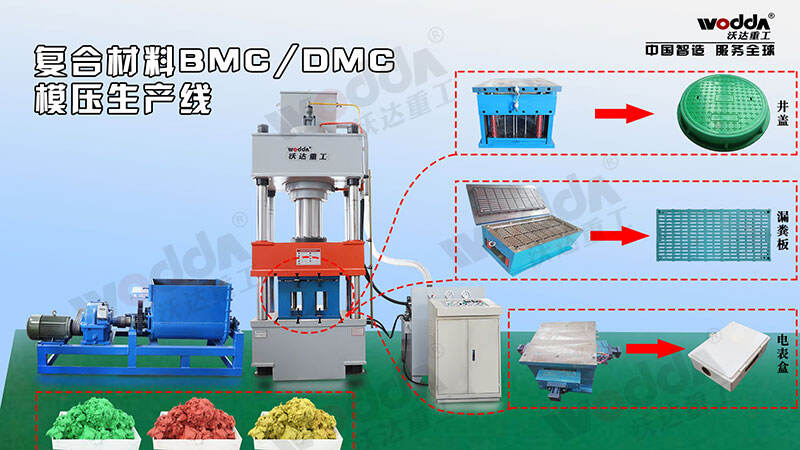

Introduction: The commonly used resin manhole cover production equipment is the resin manhole cover compression molding hydraulic press. The resin manhole cover compression molding is to add a certain amount of bulk molding compound (BMC/DMC) into the preheated mold, and solidify it after pressurization and heating. The specific process flow is adding material (adding bulk molding compound into the preheated steel mold), mold closing, mold filling (bulk molding compound flows under pressure and fills the entire cavity), curing (maintaining it at the set pressure and temperature for a certain period of time and fully curing), and opening the mold to take out the resin manhole cover product.

Composite manhole covers, also known as resin manhole covers, are made of unsaturated polyester resin and other materials (BMC or DMC for short, i.e. bulk molding compound). They are water-resistant, oil-resistant, and heat-resistant, have good electrical properties, and high impact strength, and are very popular in the market.

The commonly used resin manhole cover production equipment is the resin manhole cover compression molding hydraulic press. The resin manhole cover compression molding is to add a certain amount of bulk molding compound (BMC/DMC) into the preheated mold, and solidify it after pressurization and heating. The specific process flow is adding material (adding bulk molding compound into the preheated steel mold), closing the mold, filling the mold (bulk molding compound flows under pressure and fills the entire cavity), curing (maintaining it at the set pressure and temperature for a certain period of time and fully curing it), and opening the mold to take out the resin manhole cover product.

BMC (DMC) resin manhole cover compression molding process conditions are as follows:

⑴ Molding pressure: 3.5~7MPa for ordinary products, 14MPa for products with high surface requirements;

(2) Molding temperature: The mold temperature is 140 ± 5°C, and the fixed mold temperature can be adjusted down by 5~15°C for demoulding;

⑶Mold closing speed: mold closing must be completed within 35 seconds;

⑷ Curing time: The curing time for products with wall thickness within 3mm is about 3 minutes, the curing time for products with wall thickness of 6mm is 5-8 minutes, and the curing time for products with wall thickness of 12mm is 10-15 minutes.

BMC resin manhole cover forming hydraulic presses are commonly available in four pressures: 315 tons, 500 tons, 630 tons, and 1000 tons. They are divided into two types: one mold for one piece and one mold for multiple pieces. The mold is electrically heated. The electrical cabinet is equipped with a mold temperature display and can be adjusted. The resin manhole cover forming process shown in the above picture is a customer on-site test machine, mold test and inspection in Saudi Arabia, which was completed using a 630-ton three-beam four-column hydraulic press.

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog