Brand: Shandong Woda Heavy Machinery

Model: YQ34-630T

Origin: Tengzhou, Shandong, China

Introduction: 630-ton frame hydraulic press is also called 630-ton frame oil press and 630-ton frame press. It is called frame in contrast to the column. It is named after the fuselage structure of the equipment. The main structural parts are steel plate welded frame structure. It uses high-quality steel plates and is welded by carbon dioxide gas shielded welding. It consists of a fuselage, main oil cylinder, hydraulic pad, punching cylinder, die clamp, die lifter, die shifting arm, hydraulic system, pneumatic system, lubrication system, cooling system and electronic control system.

The 630-ton frame hydraulic press is also called a 630-ton frame oil press or a 630-ton frame press. It is called a frame in contrast to a column. It is named after the fuselage structure of the equipment. The main structural parts are steel plate welded frame structures. They are made of high-quality steel plates and welded by carbon dioxide gas shielded welding. They consist of a fuselage, a main oil cylinder, a hydraulic pad, a punching cylinder, a die clamp, a die lifter, a die shifting arm, a hydraulic system, a pneumatic system, a lubrication system, a cooling system, and an electronic control system.

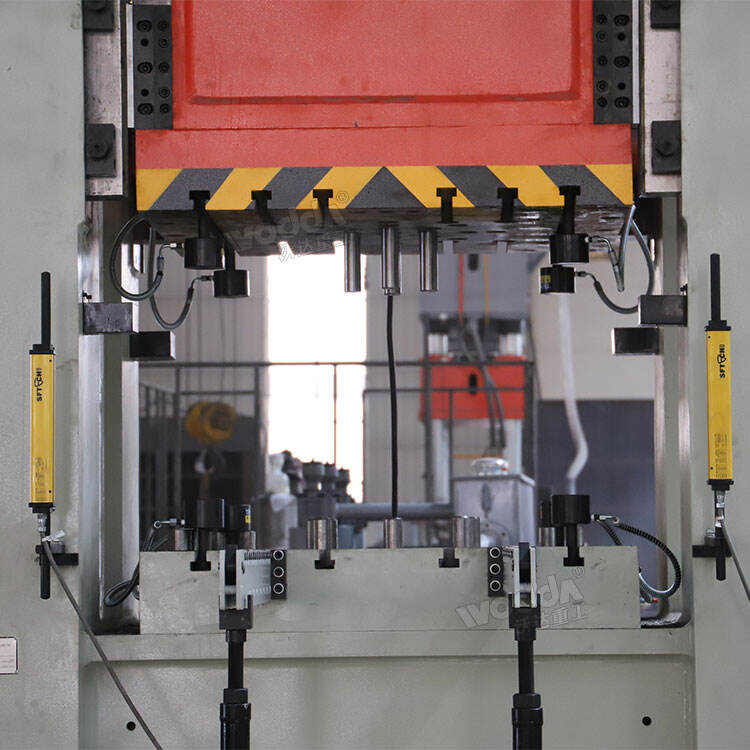

630-ton frame hydraulic press workshop test machine

630 ton frame hydraulic press

Multiple ejector rods and ejector rods

The 630-ton frame hydraulic press has an integral frame structure, with four-corner and eight-sided right-angle guide rails, high precision, good rigidity, and hydraulic preload. The hydraulic system uses a two-way cartridge integrated valve; the entire system works stably and reliably, has a long service life, less leakage, and fewer fault points. The electrical system is controlled by a "PLC" programmable controller, and can be configured with proportional pressure regulation, stroke digital display, photoelectric protection device and mobile workbench (convenient for mold replacement) according to user requirements.

630 ton frame hydraulic press performance features:

1. The hydraulic control system adopts a cartridge valve integrated system, which has reliable operation, large flow, small internal leakage, long service life, and highly integrated system, reducing connecting pipelines and leakage points.

2. Four-corner and eight-sided guide rails have high guiding accuracy, strong anti-eccentric load capacity, and centralized lubrication.

3. It adopts button centralized control, with three operation modes: adjustment, manual, and semi-automatic (fixed-range single and fixed-pressure single).

4. The slider moves fast and has high working efficiency.

5. Slider working pressure, no-load fast descent and slow speed.

6. It can be equipped with mobile workbench, punching buffer device, photoelectric protection device, punching device, slider safety bolt, etc.

630 ton frame hydraulic press technical parameters:

| Model | Model Number | YQ34-630T | ||

| Nominal force (KN) | Nominal Force | 6300 | ||

| Max opening height(mm) | Maximum Opening Height | 1500 | ||

| Slide stroke(mm) | Journey | 800 | ||

| Slide speed(mm/s) | Descent | Fast Down Speed | 280 | |

| Working | Working Speed | 5-24 | ||

| Return | Return Speed | 160 | ||

| Working table size(mm) | Left to Right (between columns) | Inside Left And Right Column | 1200 | |

| Front to Behind(side to side) | Front And Rear | 1200 | ||

| additional upper cylinder Capacity (KN) | Punching Cylinder | 630 | ||

| additional upper cylinder Capacity (clamp force) (KN) | Clamping Force | 400 | ||

| Bottom Cylinder Capacity (Ejection force) KN | Ejecting Force | 630 | ||

| Bottom Cylinder Travel (Ejection stroke) mm | Ejection Stroke | 300 | ||

| Bottom Cylinder Speed (Ejection speed) mm/s | Ejection Velocity | 100 | ||

| Press height, no more (mm) | Press Height | 6630 | ||

| Hydraulic cushion force (KN) (middle design) | Hydraulic Pad Top Power | 1600 | ||

| Hydraulic cushion size (mm) | Hydraulic Pad Size | 850*900 | ||

| Normal motor(kw) | Electric Machine | 30kw*2 | ||

| Note: |

1, Two Mold Lifter Guide Rails/Two Mold Shifting Arms 2, 12 Punching Rod Holes; 3, Slide Lock Device; 4, Industrial Air Conditioning. |

|||

Note: The above parameters are for reference only.

Application areas:

This series of hydraulic presses are suitable for various stamping processes such as stretching, blanking (blanking buffer device should be selected), bending, flanging, cold extrusion, etc. of metal materials. They are also suitable for straightening, pressing, pressing and forming of powder products and abrasive products, as well as pressing of plastic products and insulating materials.

Optional accessories:

Mobile workbench; punching buffer device; photoelectric protection device; stroke, pressure, speed digital display, CNC device, touch-type industrial display screen, hydraulic system heating and cooling device; punching device; slide safety bolt; mold heating and temperature control device; floating guide rail and rolling bracket for mold changing, etc.

Shandong Woda Heavy Industry, a manufacturer of frame hydraulic presses , is committed to the research and development and production of 200-ton, 315-ton, 400-ton, 500-ton, 630-ton, 800-ton, 1000-ton, 1200-ton, 2000-ton and 3000-ton frame hydraulic presses, frame-type thin plate stamping presses, frame-type thin plate stretching presses. It can also customize multifunctional frame hydraulic presses (oil presses) on demand.

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog