Brand: Shandong Woda Heavy Machinery

Model: Four-beam four-column hydraulic press

Origin: Tengzhou, Shandong, China

Introduction: 800-ton metal powder briquetting machine_800-ton four-beam four-column hydraulic press, table 1400x1200mm, integrating machinery, electricity, hydraulics and gases, equipped with automatic feeding device, realizing automatic feeding, pressing, demoulding and block automation, realizing double-sided pressurization molding through mold frame floating, making the molding density uniform and improving the appearance quality of demoulding products, the hydraulic system adopts combined superposition valve block to realize continuous full-load operation without failure.

The 800-ton four-beam four-column hydraulic press is a common powder forming hydraulic press, which can be used for the pressing and forming of powder products such as metal powder, ceramic powder, graphite powder, and non-metallic powder. It can also be used as a double-action thin plate stretching machine to realize the deep drawing process of the plate. Compared with the three-beam four-column hydraulic press, the 800-ton four-beam four-column hydraulic press has an extra demoulding beam, which is convenient for protective demoulding. It adopts hydraulic transmission and computer control, has a low failure rate, stable operation, fast action, and standard seals, so as to ensure that the cylinder pressure is not weakened during continuous operation. It is easy to maintain, durable, and has low wear. This article is an 800-ton metal powder briquetting machine_800-ton four-beam four-column hydraulic press.

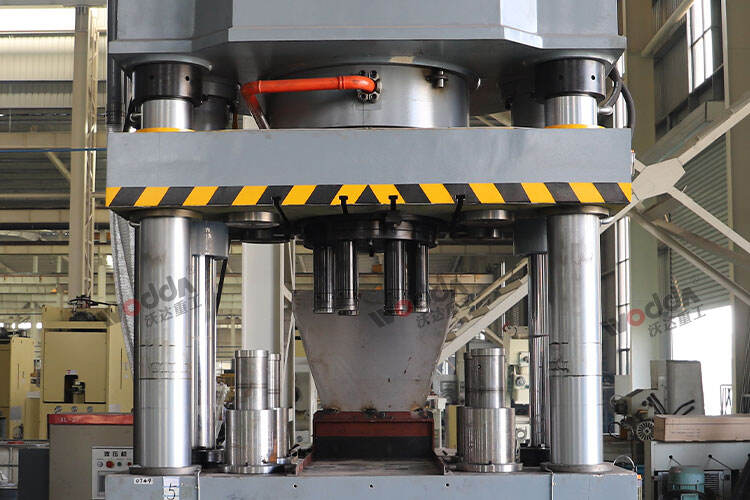

800 ton four-beam four-column hydraulic press

Metal powder compact application

800 ton metal powder briquetting machine_800 ton four-beam four-column hydraulic press, table 1400x1200mm, integrated with machinery, electricity, hydraulic and gas, equipped with automatic feeding device, realizes automatic feeding, pressing, demoulding and block automation, realizes double-sided pressurization molding through mold frame floating, makes its molding density uniform, improves the appearance quality of demoulding products, and the hydraulic system adopts combined superposition valve block to achieve continuous full-load operation without failure. The molding limit switch is adjusted according to the technical parameters to achieve stable and adjustable size of the molded product. Equipped with water cooling device to avoid excessive oil temperature. The PLC human-machine interface control system is adopted to realize the full automation of the equipment.

800 ton metal powder briquetting machine_800 ton four-beam four-column hydraulic press workshop display:

3 800 ton metal powder briquetting machines

800 ton metal powder forming hydraulic press

Workbench and mold opening cylinder

800 ton metal powder briquetting machine_800 ton four-beam four-column hydraulic press technical parameters:

Equipment model: 800T

Nominal pressure: 8000KN

System pressure: 25Mpa

Slider stroke: 600mm

Opening height: 1600mm

Working table effective area: 1400x1200mm

Note: The parameters of the 800-ton four-beam four-column hydraulic press are for reference only and need to be adjusted according to actual needs.

800 ton metal powder briquetting machine_800 ton four-beam four-column hydraulic press is mainly composed of the following components:

① Main machine: It consists of a frame, a main hydraulic cylinder, a pusher hydraulic cylinder, a bottom plate hydraulic cylinder, a matching mold frame and mold, a pressure head, etc.

② Frame: It is composed of upper and lower beams and columns. The upper and lower beams are all made of high-quality steel parts. The upper and lower beams are connected by four columns with internal and external nuts to bear the tension during work.

③ Main oil cylinder: It is composed of cylinder body, piston head, piston rod, guide sleeve and sealing ring. The cylinder system is made of forged steel. The oil cylinder is fastened to the upper crossbeam by the lower flange and the upper locking nut. The lower end of the piston rod is connected to the movable crossbeam through the connecting nut and bolt. When the upper or lower chamber of the main cylinder is filled with oil, the movable crossbeam is driven downward or returned.

④Hydraulic station: It is composed of motor, hydraulic pump, pump protection device, professional control valve block and pipeline system for connecting briquetting machine. It has reasonable design and stable quality.

⑤Control console: It consists of electrical system and PLC control system.

⑥Equipped with an adjustable text display, the action sequence and each action time are completely controlled by the PLC system and can be adjusted by the operator at any time, which is convenient, fast, simple and easy to understand.

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog