Brand: Shandong Woda Heavy Machinery

Model: YQ41 series

Origin: Tengzhou, Shandong, China

Introduction: BDF water tank punching machine is a 120-ton single-column hydraulic press and a 200-ton single-column hydraulic press purchased by customers. It is mainly used for punching BDF water tank plates. The C-type single-arm structure design makes it compact and easy to operate, while providing sufficient pressure and stability. This series of hydraulic presses is suitable for various processes such as stamping, pressing, bending, stretching, shearing, and punching of various metal materials.

This article introduces the BDF water tank punching machine, which is a 120-ton single-column hydraulic press and a 200-ton single-column hydraulic press purchased by the customer. It is mainly used for punching BDF water tank plates. The C-type single-arm structure design makes it compact and easy to operate, while providing sufficient pressure and stability. This series of hydraulic presses is suitable for various processes such as stamping, pressing, bending, stretching, shearing, and punching of various metal materials.

BDF water tank punching machine - 120 tons 200 tons single column hydraulic press machine body is welded with steel plates, with sufficient rigidity and stability. The hydraulic system is located inside the machine body, with beautiful appearance and convenient operation. This series of presses is equipped with independent hydraulic and electrical control systems, using button centralized control, which can realize two molding processes of fixed stroke and fixed pressure, and has functions such as pressure display and stroke and pressure adjustment.

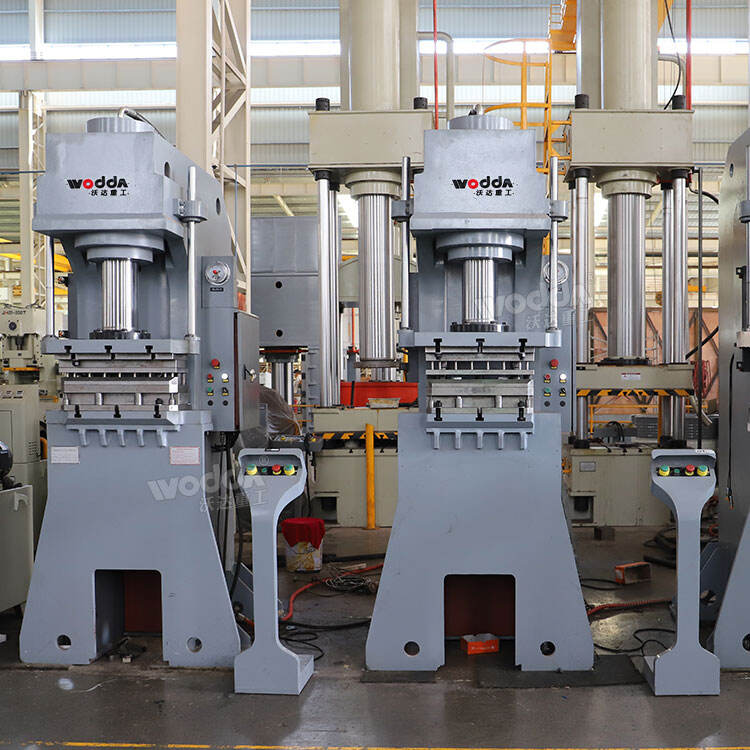

BDF water tank punching machine - 120 tons 200 tons single column hydraulic press workshop display:

BDF water tank punching machine

2-table 120-ton single-column hydraulic press

200 ton single column hydraulic press

Uses and features:

① Single-column hydraulic press is widely used in the stretching, forming and pressing of metal products. It can also be used for processing non-metallic materials, pressing of powder metallurgy products, correction of shaft parts, pressing of sleeve parts, shaping and trimming of metal products.

②This machine has an independent power structure and electrical system, and adopts centralized button control to realize inching and semi-automatic operation.

③ The working pressure, pressing speed and stroke range of this machine can be adjusted arbitrarily within the specified range according to needs. It can also complete two process modes: upper pressing and fixed stroke forming. In semi-automatic operation, both process modes have pressure holding delay and automatic return action after pressing.

Optional accessories or features:

☆ Grating safety protection device

☆ Touch screen display system for stroke, pressure and time

☆PLC programmable controller

☆ Punching buffer device

☆ Floating guide rails and rolling brackets for mold change

☆ Various forms of mobile workbenches

☆ Fast stroke flushing device

Performance and structure:

①The machine body adopts a single-arm structure: it consists of a workbench, a main cylinder, a hydraulic power system, an electrical system, etc. The whole machine is welded with high-quality Q235 steel plates, and the welding stress is eliminated through aging treatment.

②The tonnage of the pressing cylinder is realized by a piston cylinder. The cylinder body is made of high-quality 45# steel, and the surface of the piston rod is treated with medium-frequency quenching, which has a long service life. The main components of the oil cylinder are made of high-quality material sealing rings to ensure reliable sealing.

Hydraulic system:

①The hydraulic system device is arranged inside the fuselage.

②The hydraulic pump station consists of an oil tank, a high-pressure pump, an electric motor, a reversing valve, etc. The oil tank is welded with steel plates. The oil tank is a closed oil tank with an oil drain plug to facilitate cleaning and oil replacement.

③The hydraulic system is reliably sealed and leak-proof. The main pipelines are connected by flanges and the pipelines are equipped with shock-proof measures.

Electrical control system:

①The electrical cabinet is equipped with air switches, relays and other electrical appliances.

② Realize program interlocking for various signals, limit and pressure actions of the press.

③There is a centralized control panel with necessary operation buttons and selection switches.

How to operate:

①The press machine is equipped with inching and semi-automatic operation modes.

②The stroke can be adjusted.

③In addition to completing all the actions of the press, the buttons on the operation panel also include an "emergency stop" button.

Security protection:

① Set an emergency stop button. Press the emergency stop button and the press will stop immediately.

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog