Brand: Shandong Woda Heavy Machinery

Model: Four-beam four-column hydraulic press

Origin: Tengzhou, Shandong, China

Introduction: 315-ton powder forming hydraulic press is a customized flange forming equipment with a four-beam four-column structure, also known as a 315-ton four-beam four-column hydraulic press. It uses servo motors and servo systems. It is mainly used for powder metallurgy of structural parts and the production of mechanical parts. It is also suitable for the pressing and forming of precision ceramics, electronic ceramics and hard synthetic gold products.

The 315-ton powder forming hydraulic press is a customized flange forming equipment with a four-beam four-column structure, also known as a 315-ton four-beam four-column hydraulic press. It uses servo motors and servo systems. It is mainly used for powder metallurgy of structural parts and the production of mechanical parts. It is also suitable for the pressing and forming of precision ceramics, electronic ceramics and hard synthetic gold products.

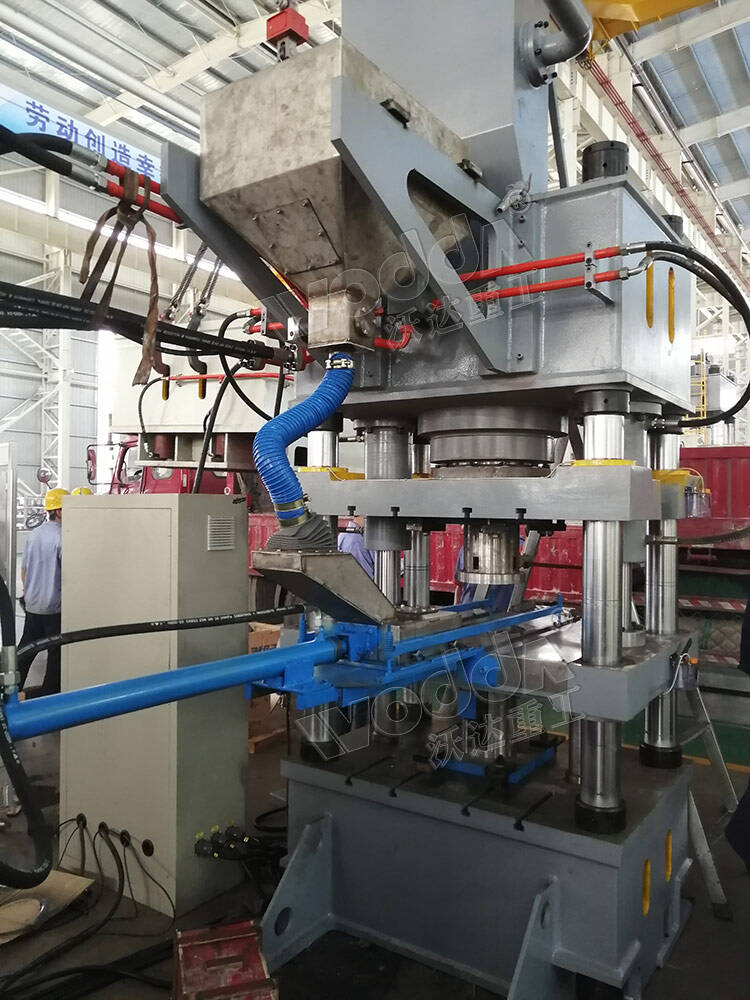

Actual photos of the 315-ton powder forming hydraulic press workshop:

315 ton four-beam four-column hydraulic press workshop diagram

315 tons powder forming hydraulic press

Automatic feeding device

315 tons powder forming hydraulic press

Flange powder forming

315 ton powder forming hydraulic press technical parameters (for reference only):

| Model/technical parameters | Unit | 315T |

| Nominal pressure | KN | 3150 |

| System pressure | MPa | 25 |

| journey | mm | 500 |

| Maximum opening height | mm | 500 |

| Table area | (mm*mm) | 1000*1000 |

Note: The above parameters are for reference only.

Features of 315 ton powder forming hydraulic press:

1. The main machine of the 315-ton powder forming hydraulic press is constructed of steel plate welded parts, which has good rigidity, strong stability, smooth operation, no noise, and extends the service life of the machine.

2. It adopts domestic PLC hydraulic transmission technology with a high degree of automation, which reduces the labor intensity of workers and improves work efficiency.

3. Adopting unique pressing molding process, the molding pressure is high, the pressed product is of good quality, not easy to break, and has beautiful appearance.

4. Hydraulic components are made of high-quality hydraulic components, and the pump station can achieve continuous normal operation with a low failure rate.

5. The electrical control cabinet of the 315-ton four-beam four-column hydraulic press adopts centralized button control, which is easy to learn and understand and convenient for users to operate.

6. Replacing the mold can produce products of different shapes, ensuring the diversified needs of products.

The 315-ton four-beam four-column hydraulic press has independent hydraulic and electrical systems, automatic feeding and unloading device, floating pressing, so that the product molding density can be effectively controlled. Two demoulding methods are available: protective demoulding and general demoulding. The electrical control adopts PLC programmable controller, and the hydraulic system adopts advanced plug-in integrated valve to ensure the continuous, frequent and stable operation of the hydraulic press. It adopts button centralized control, and can also be equipped with mechanical limit devices to ensure the consistency of the products. It can be equipped with high-precision mold frames, and the molds and mold frames are easy to replace; the upper punch has a delayed return device to avoid cracking of the pressed blank during demoulding. The pull-down mold frame can be used to press complex shapes, uniform density, and high-precision pressed blanks.

315 ton powder night forming hydraulic press test video:

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog