Brand: Shandong Woda Heavy Machinery

Model: JH21 series

Origin: Tengzhou, Shandong, China

Introduction: Shandong Woda Heavy Machinery CO.,LTD. is a professional punching equipment manufacturer in Tengzhou. The company's products have been studied and improved many times in practice, and have the characteristics of strong versatility, high precision, reliable performance, and easy operation. They are widely used in stamping, shearing, bending, punching, blanking, stretching, and forming of metal and non-metal materials.

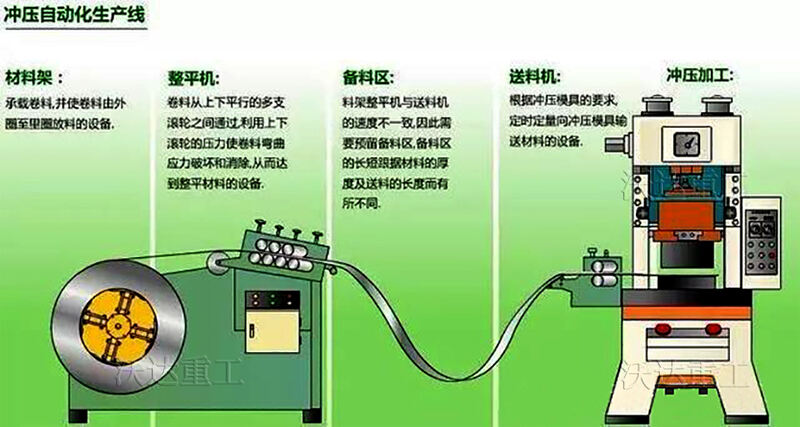

JH21 pneumatic punch press , also called pneumatic press, open single-point fixed table press, is a commonly used machine equipment in modern industrial production. As shown in the following figure:

JH21 series pneumatic punch press has the following features:

1. The machine body is welded with high-quality steel plates, and its rigidity is better than that of general machine tools;

2. Equipped with overload protection device, which is sensitive and reliable, can protect the mold and machine tools, and can restore the machine tools to use in a short time;

3. Adopt PLC electrical control system, stable and reliable;

4. Closed gear transmission, oil-immersion lubrication, smooth transmission and low noise;

5. It adopts combined pneumatic clutch-brake and imported friction materials, which has a long service life;

6. Optional frequency converter to support speed regulation;

7. Adjust the gap through the balancer to effectively ensure the working accuracy;

8. Air cushion, automatic mold adjustment device, photoelectric protection device, automatic feeding device, fast mold change device, unwinder and straightener are optional.

Technical parameter table of JH21 pneumatic punch press

| Serial number | Type [model] | 25 T | 45 T | 63 T | 80 T | 125 T | |

| 1 | Nominal capacity | 250kN | 450kN | 630kN | 800kN | 1250kN | |

| 2 | Impulse position | mm | 3 | 4 | 4 | 5 | 5 |

| 3 | Length of travel [slider travel] | mm | 80 | 100 | 120 | 140 | 160 |

| 4 | Maximum closed working height [maximum mold loading height] | mm | 250 | 270 | 300 | 320 | 370 |

| 5 | Number of strokes/minutes [ Number of slider strokes ] | s.p.m | 100 | 80 | 70 | 60 | 50 |

| 6 | Slider adjustment | mm | 50 | 60 | 80 | 80 | 100 |

| 7 | Throat depth | mm | 210 | 230 | 300 | 300 | 370 |

| 8 | Upper table size [ Slide surface size ] | LRXFBXT | 250x360 | 340x410 | 400x480 | 420x560 | 520x620 |

| 9 | Lower table size [ Table size ] | LRXFBXT | 700x400 | 810x440 | 900 x580 | 1000x580 | 1120x720 |

| 10 | Main motor [ Main motor ] | KWXP | 3x4 | 5.5x6 | 5.5x6 | 7.5x4 | 11x4 |

| 11 | Type [model] | 160 T | 200 T | 250 T | 315 T | 400 T | |

| 12 | Nominal capacity | 1600kN | 2000kN | 2500kN | 3150kN | 4000kN | |

| 13 | Impulse position | mm | 6 | 6 | 8 | 8 | 10 |

| 14 | Length of travel [slider travel] | mm | 180 | 200 | 200 | 200 | 200 |

| 15 | Maximum closed working height [maximum mold loading height] | mm | 400 | 450 | 450 | 430 | 430 |

| 16 | Number of strokes/minutes [ Number of slider strokes ] | s.p.m | 45 | 40 | 40 | 30 | 25 |

| 17 | Slider adjustment | mm | 110 | 110 | 110 | 120 | 120 |

| 18 | Throat depth | mm | 390 | 430 | 450 | 420 | 420 |

| 19 | Upper table size [ Slide surface size ] | LRXFBXT | 580x700 | 650x880 | 700x930 | 650x850 | 650x850 |

| 20 | Lower table size [ Table size ] | LRXFBXT | 1200x760 | 1400x840 | 1500 x880 | 1400x800 | 1400x800 |

| 21 | Main motor [ Main motor ] | KWXP | 15x6 | 18.5x6 | 22x6 | 30x6 | 37x6 |

JH21 Pneumatic Punch Machine Configuration List

|

Standard accessories |

Special accessories |

||||

|

Oil pressure overload protection device |

Formula 1 |

○ |

Manual grease lubrication device |

Formula 1 |

|

|

Electric slide adjustment device |

Formula 1 |

○ |

Main motor reversing device |

Formula 1 |

|

|

Electric grease lubrication device |

Formula 1 |

○ |

Slider upper ejection device [slider ejection rod] |

Formula 1 |

|

|

Slider and mold balancing device |

Formula 1 |

○ |

Preset counter (6 digits) |

1 Group |

|

|

Electronic Cam (PAC10) Controller |

1 Group |

○ |

Maintenance hour timer |

1 Group |

|

|

Pointer crankshaft angle indicator |

Formula 1 |

○ |

Photoelectric safety device |

Formula 1 |

|

|

Digital mold height indicator (0.1mm) |

1 Group |

○ |

Power socket (120 type) single phase. Type II. Two poles. 220V. 10A |

Group |

|

|

Fixed speed motor |

1 Group |

○ |

Power socket (120 type) single phase. Y type. three poles. 220V. 10A |

Group |

|

|

Programmable Controller PLC |

1 Group |

○ |

Shockproof device S78-10-06 |

Formula 1 |

|

|

Maintenance tools and tool boxes |

1 Set |

○ |

Mould lighting |

Formula 1 |

|

|

Operating Instructions and Inspection Results Sheet (Chinese Version) |

1 Serving |

○ |

T-type operating table |

1 Group |

|

|

○ |

Automation peripheral equipment (see attachment for detailed specifications) |

1 Serving | |||

|

○ |

Quick mold change device (see attachment for detailed specifications) |

1 Serving | |||

|

○

|

Barrelless air pressure die pad device [Stretching pad] SA-3.6 1 set Capacity: 3.6 ton Stroke: 70mm Die pad area: 440 × 300 mm² |

||||

|

○ |

Air blowing connector (1/2") 1 set, additional |

Group |

|||

|

○ |

Air source connector (1/2") 1 set, additional |

Group |

|||

|

○ |

Safety Net |

Formula 1 |

|||

|

○ |

Misdelivery detection of metal socket |

1 Group |

|||

Shandong Woda Heavy Machinery CO.,LTD.

is a professional punching equipment manufacturer in Tengzhou. The company's products have been studied and improved many times in practice. They have the characteristics of strong versatility, high precision, reliable performance, and easy operation. They are widely used in stamping, shearing, bending, punching, blanking, stretching, and forming of metal and non-metal materials.

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog