The automobile power pool shell stretching hydraulic press adopts a frame hydraulic press structure and is equipped with a progressive die. It has the characteristics of fast stretching speed, high processing efficiency, high processing precision, convenient operation, safety and reliability, etc. The standard tonnage is 315 tons, 400 tons and 500 tons.

With the development of economy and society, new energy vehicles, especially electric vehicles, are becoming more and more popular and sought after by the society. The main power of electric vehicles comes from power batteries, which are the heart of electric vehicles. In view of the actual application and development trend of aluminum alloy power battery shells in the current market, hydraulic press manufacturer Woda Heavy Industry has newly developed a hydraulic press for stretching aluminum battery shells. The standard tonnage is 315 tons, 400 tons and 500 tons.

The depth of the aluminum alloy battery shell exceeds 20CM, which belongs to the deep drawing process and requires multiple gradual stretching to form. In view of this, we have developed this automotive battery cell shell stretching hydraulic press and configured it with progressive die stretching. In order to improve product precision and facilitate demoulding, we specially adopted a frame structure hydraulic mainframe.

The frame of the main machine of the automobile power pool shell stretching hydraulic press has four to six stations arranged in sequence from the feeding side to the discharging side, which are shallow drawing station, secondary stretching station, stretching completion station, primary shaping station, secondary shaping station and trimming and deburring station. A feeding mechanism is arranged between the stations, and the station includes a mold mechanism, and the mold mechanism includes an upper mold and a lower mold. The upper mold adopts a hydraulic device to provide power for it, and the lower mold adopts a pneumatic device to push out the semi-finished product. The pneumatic device, hydraulic device, and feeding mechanism are all controlled by the control panel on the electrical cabinet through the circuit. A grating protection device is arranged on the same side as the control panel from the feeding side to the discharging side of the frame.

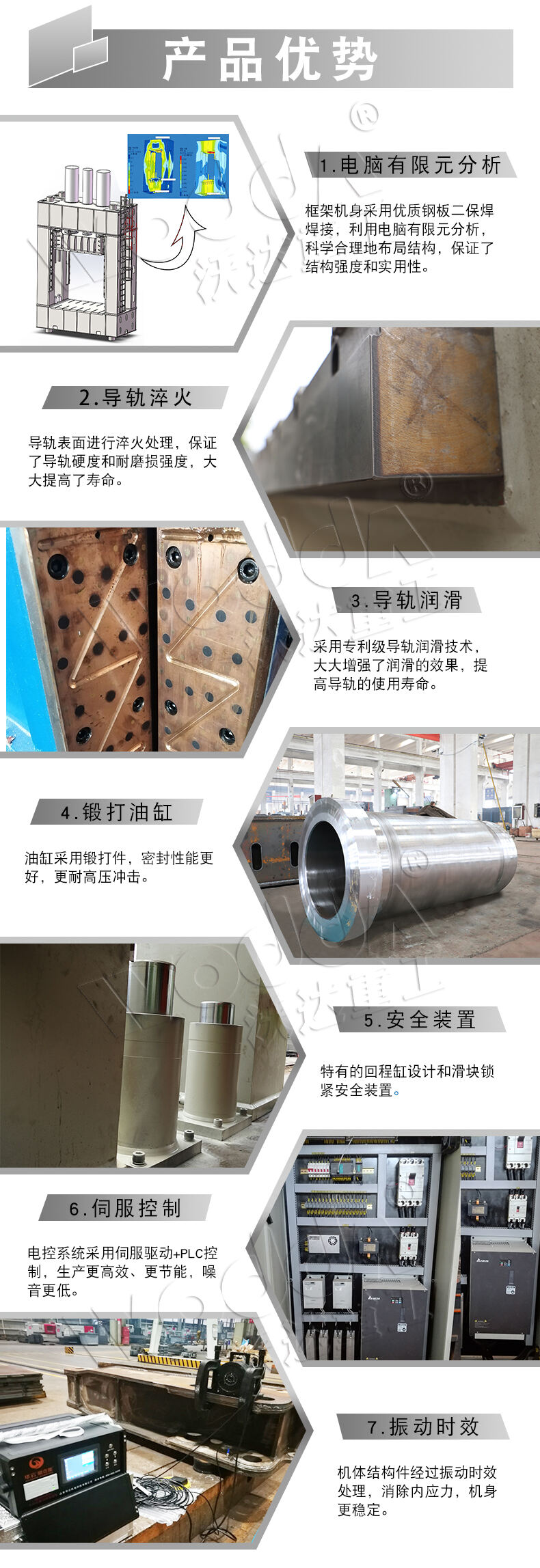

Detail of hydraulic press for stretching the shell of power pool of new energy vehicle

Shandong Woda Heavy Industry is a hydraulic press manufacturer focusing on the research and development, production and service of large and medium-sized forging machine tools. Its main products include three-beam four-column hydraulic press, four-beam four-column hydraulic press, single-column hydraulic press, gantry hydraulic press, frame hydraulic press, powder forming hydraulic press, metal stretching hydraulic press, FRP mold pressing hydraulic press, composite material forming hydraulic press, forging hydraulic press, punch press, press straightening machine and various supporting molds (punching, stretching, molding, forging), etc. Its customers cover more than 300 cities in China and overseas regions such as Central Asia, Europe, Africa, South America, etc.

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog