Brand: Shandong Woda Heavy Machinery

Model: YQ34-2500T

Origin: Tengzhou, Shandong, China

Introduction: This is a 2500-ton frame hydraulic press, which is a customized hydraulic equipment for molding SMC bathroom chassis, also known as SMC integral bathroom hydraulic press. The equipment body is an integral frame structure, welded with all-steel plates, and CO2 gas shielded welding is used. Vibration aging treatment is performed after welding to eliminate welding stress, so that it has good strength and rigidity. The body is processed on a large CNC boring and milling machine to ensure processing accuracy, and T-slots are processed on the plane of the workbench to facilitate mold installation.

SMC integrated bathroom products are mostly molded with SMC materials, including bathtubs, bath racks, wash basins, toilets, chassis, wall panels, etc. Among them, SMC chassis, wall panels, etc. require a hydraulic press of more than 2,000 tons to produce them in one-time molding. SMC integrated bathroom products have high density, high strength, smooth surface, excellent electrical insulation performance, mechanical properties, thermal stability, and chemical corrosion resistance.

This article is a 2500-ton frame hydraulic press, which is a customized hydraulic equipment for molding SMC bathroom chassis, also known as SMC integral bathroom hydraulic press. The equipment body is an integral frame structure, welded with all-steel plates, and CO2 gas shielded welding is used for welding. Vibration aging treatment is performed after welding to eliminate welding stress, so that it has good strength and rigidity. The body is processed on a large CNC boring and milling machine to ensure processing accuracy, and T-slots are processed on the plane of the workbench to facilitate mold installation.

2500 ton SMC integrated bathroom hydraulic press is one of the composite hydraulic press series, mainly suitable for thermosetting and thermoplastic and other various plastic materials compression molding, product size is large and high precision requirements, the frame structure is preferred. It is widely used in the transportation industry such as automobile, aviation, high-speed rail, and home and power industries, and is used for compression molding of composite materials such as SMC/BMC/DMC/GMT/LFT/PCM.

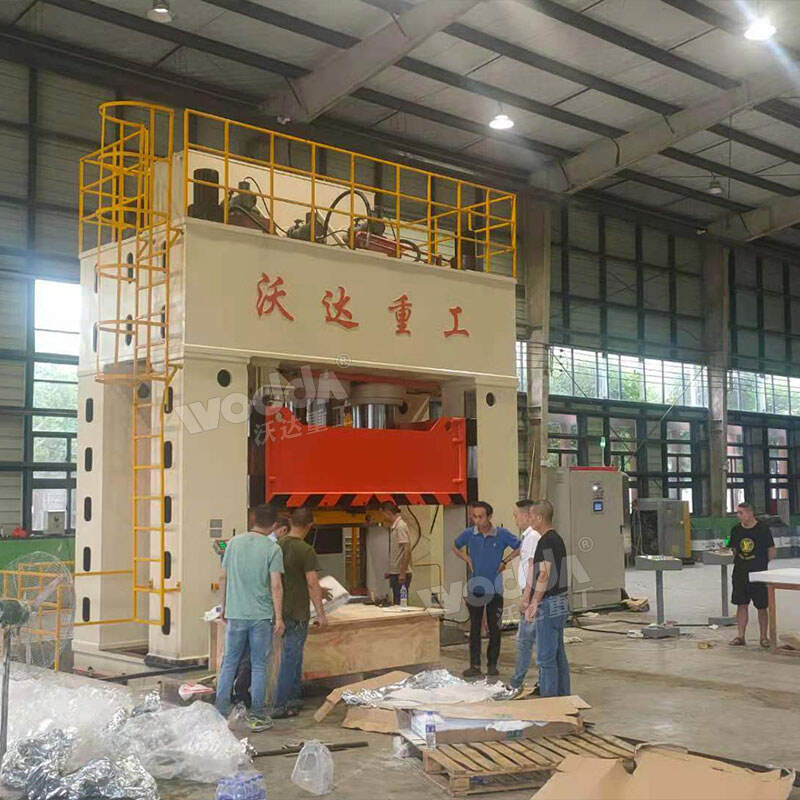

2500 tons frame hydraulic press

2500 ton frame hydraulic press installation completed

The 2500-ton frame hydraulic press adopts a four-corner and eight-sided rectangular rail with adjustable gap and good rigidity, which can effectively eliminate the influence of thermal expansion of the machine on the guide rail gap; the slider is high, the contact surface with the guide rail is large, and the anti-eccentric load ability is strong; the precision is high, and the repeat positioning accuracy and parallel accuracy are high; the main cylinder is fixed on the upper beam by a nut, the cylinder body is made of high-quality carbon steel, the piston rod surface is quenched, and the cylinder seal should use an anti-aging and sealing ring with good sealing performance.

Frame: The frame of the frame hydraulic press is the main load-bearing part of the entire machine. It is usually welded from thick steel plates. It has high rigidity and stability and can effectively resist vibration and deformation during processing.

Hydraulic cylinder: The hydraulic cylinder is one of the core components of the hydraulic press, responsible for generating pressure and driving the piston to move. The hydraulic cylinder is equipped with sealing elements to ensure the sealing performance of the hydraulic system.

Piston and piston rod: The piston is the moving part in the hydraulic cylinder and is sealed by a seal ring. The piston rod is connected to the piston and is responsible for transmitting the force of the hydraulic cylinder to the workpiece. The piston rod is usually surface treated to improve its wear resistance and corrosion resistance.

Workbench: The workbench of the 2500-ton frame hydraulic press is a platform for placing and fixing workpieces, usually located on the upper part of the frame. The size and shape of the workbench can be designed and adjusted according to processing needs, and usually has sufficient strength and stability.

Hydraulic system: The hydraulic system is the power source of the frame hydraulic press, including oil tanks, pump stations, oil pipes, control valves and other components. The hydraulic system adjusts the hydraulic oil flow in the hydraulic cylinder through the control valve to control the movement of the hydraulic cylinder and the processing parameters.

Control system: The control system is used to control and adjust the processing of the hydraulic press. The control system includes electrical control cabinets, control buttons, sensors, etc., which can monitor and adjust the processing parameters to ensure the accuracy and stability of the processing process.

2500 ton frame hydraulic press equipment is controlled by PLC system, with stable pressure, high efficiency, high yield, flexible pressurization, fast vacuum, slow multi-stage pressurization, and multi-stage heating. The holding time is adjustable, and the pressure, speed, and stroke required during work can be adjusted within a certain range. There are three operating modes: manual, semi-automatic, and fully automatic. It adopts servo closed-loop control system, which has the advantages of energy saving and low noise.

2500 ton SMC integrated bathroom hydraulic press site

SMC integrated bathroom hydraulic press on-site commissioning

Bathroom chassis

Features of SMC integrated bathroom hydraulic press:

1. SMC integrated bathroom hydraulic press is designed by computer optimized structure, which is simple, economical and practical.

2. The hydraulic control adopts a cartridge valve integrated system, which has reliable operation, long service life, small hydraulic shock, and reduces connecting pipelines and leakage points.

3. SMC integrated bathroom hydraulic press has an independent electrical control system, which is reliable in operation, intuitive in action and easy in maintenance.

5. Through the operation panel selection, two operation processes of fixed stroke and fixed pressure can be realized, and it has functions such as pressure holding and delay.

6. The working pressure of the slider, the range of no-load fast descent and slow working advance can be adjusted according to work needs.

7. PLC servo system control, pressure holding time is adjustable, the pressure, speed and stroke required during work can be adjusted within a certain range, manual, semi-automatic and fully automatic operation modes.

8. The working pressure, pressing speed, high-pressure downward movement, no-load rapid downward movement and ejection stroke of SMC integrated bathroom hydraulic press are controlled by pressure sensors, micro-speed regulating valves, inductive sensors, displacement sensors, etc. The force, time and stroke parameters can be adjusted on the touch screen through PLC according to the pressing process requirements of different products to ensure product quality and high consistency.

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog