Brand: Shandong Woda Heavy Machinery

Model: WDA series precision punch press

Origin: Tengzhou, Shandong, China

Introduction: WDA-110 ton precision punch press is a high-efficiency, high-precision punching equipment, widely used in a variety of mass production of metal sheet metal processing, including punching, forming, stretching and other processes. This punch press plays an important role in the processing of transportation vehicles, clocks and watches, home appliances, stationery, hand tools, hardware, computers and other products.

WDA-110 ton precision punch press is a high-efficiency, high-precision punching equipment, which is widely used in a variety of metal sheet processing in mass production, including punching, forming, stretching and other processes. This punch press plays an important role in the processing of transportation vehicles, clocks and watches, home appliances, stationery, hand tools, hardware, computers and other products.

Main features of WDA-110 ton precision punch press:

High rigidity

1. High rigidity and high precision structure, welded with steel plates, heat treated to eliminate the pressure inside the bed.

2. The structural parts are evenly loaded and rigidly balanced.

Stable high precision

The friction parts such as crankshaft, gears, gear shafts, etc. are hardened and heat treated before grinding, and have extremely high wear resistance and balance, and stable performance.

Reliable and safe operation

The clutch/brake device is highly sensitive, and together with the double solenoid valve and overload protection device, it ensures the accuracy and safety of the operation and stopping of the punch slide.

Production automation and labor saving

It can be matched with any automatic feeding mechanism to run automated production, reduce costs and improve efficiency.

Balanced center of gravity

1. The transmission center is consistent with the center of the whole machine, ensuring the precision and stability of stamping.

2. This machine uses two slider balancers to ensure that the machine maintains balanced operation.

Slider adjustment mechanism

The adjustment precision is up to 0.1mm, making production adjustment safer and faster.

Environmental friendly

Advanced design concept, low noise, low consumption, energy saving.

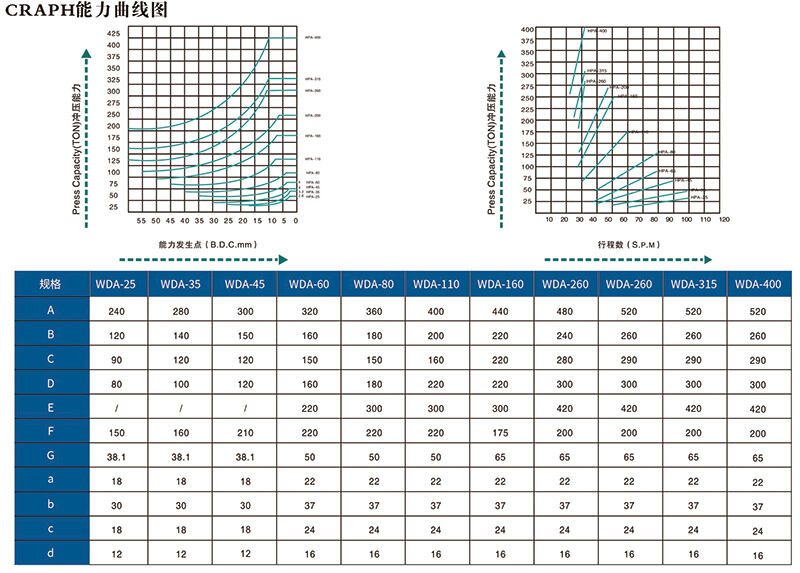

WDA-110 ton precision punching machine technical parameters:

| Specification | Specification | Unit | WDA-80 | WDA-110 | WDA-160 | |||||

| Type | Model | V | H | V | H | V | H | |||

| Ton | Capacity | tom | 80 | 110 | 160 | |||||

| Where the impulse occurs | Ratedtonnage point | mm | 4 | 2 | 6 | 3 | 6 | 3 | ||

| Trips per minute | Constant speed | Speed changing | s.p.m | 35-80 | 80-120 | 30-60 | 60-90 | 20-50 | 40-70 | |

| Variable speed | Stable speed | s.p.m | 65 | 50 | 35 | |||||

| Journey | Stroke | mm | 150 | 70 | 180 | 80 | 200 | 90 | ||

| Maximum closed working height | Die height | mm | 340 | 380 | 360 | 410 | 460 | 510 | ||

| Slider adjustment amount | Slide adjustment | mm | 80 | 80 | 100 | |||||

| Top table size | Type I | Slide area | mm | 560x420x70 | 650x470x80 | 700x550x90 | ||||

| Type II | Slide area | mm | 770x420x70 | 910x470x80 | 910x500x80 | |||||

| Lower table size | Bolster area | mm | 1000x550x90 | 1150x600x110 | 1250x800x140 | |||||

| Shank hole | Shankhole | mm | Φ50 | Φ50 | Φ65 | |||||

| Main motor | Main motor | kw.p | 7.5x4 11x4 15x4 | |||||||

| Slider adjusting mechanism | Slide adjust device | HP | electrical driving | |||||||

| Service air pressure | Air pressure | kg/c㎡ | 6 | 6 | 6 | |||||

| Punch accuracy | Presses precision | GB/JIS 1class | ||||||||

| Punching machine (L x W x H) | Presses dimension | mm | 1800x1180x2800 | 1900x1300x3200 | 2300x1400x3800 | |||||

| Punch weight | Presses weight | Ton | 6.5 | 9.6 | 16 | |||||

| Die pad capacity | Die cushion capacity | Ton | 3.6 | 6.3 | 10 | |||||

| Die pad travel long | Stroke | mm | 70 | 80 | 80 | |||||

| Effective area of die pad | Die cushion effective area | m㎡ | 450x310 | 500x350 | 650x420 | |||||

Copyright © Shandong Woda Heavy Machinery Co., Ltd. All Rights Reserved. - Privacy Policy - Blog